Inquiry

Form loading...

Choosing the right lock nuts for your projects is crucial. In the fast-paced world of engineering, failure can be costly. According to a report by the Engineering Failure Analysis journal, about 30% of mechanical failures stem from improper fastener selection. Lock nuts play a vital role in preventing loosening due to vibrations. The global demand for lock nuts is projected to grow steadily at 5% annually, highlighting their importance in various industries.

However, not all lock nuts are created equal. Choosing the right material and type is essential. Common types include nylon insert, all-metal, and serrated. Each type has its pros and cons. A mismatch can lead to safety risks and performance issues. Recent studies indicate that 15% of structural failures relate to incorrect fastener use. This statistic should prompt a reevaluation of choices made in your projects.

Selecting lock nuts involves careful consideration of application and environment. Factors like load, temperature, and vibration frequency must be assessed. A common misstep is underestimating environmental effects. Materials may degrade over time if not suited for specific conditions. A thorough understanding of these details can better inform your choices and prevent future complications.

Lock nuts come in various types, each suited for specific applications. The most common types include nylon insert lock nuts, all-metal lock nuts, and split lock nuts. Nylon insert lock nuts provide excellent resistance to vibration. According to industry reports, they decrease the risk of loosening by 70%, making them ideal for automotive and machinery applications.

All-metal lock nuts, such as deformed-thread types, offer higher strength and durability. They perform well in extreme temperatures and harsh environments. In fact, data from mechanical engineering studies reveal these nuts can withstand loads exceeding their standard counterparts by 30%. On the other hand, split lock nuts might be simpler, but they often require careful judgment. Their effectiveness in preventing loosening is well-documented, yet they may not hold as well under dynamic loads.

Choosing the right type of lock nut involves considering the specific project requirements, including material compatibility, environmental conditions, and load-bearing needs. It’s crucial to reflect on whether a robust solution like an all-metal lock nut is necessary. Or, is a nylon insert sufficient? Making the right choice can significantly impact your project's success, but it takes thoughtful evaluation.

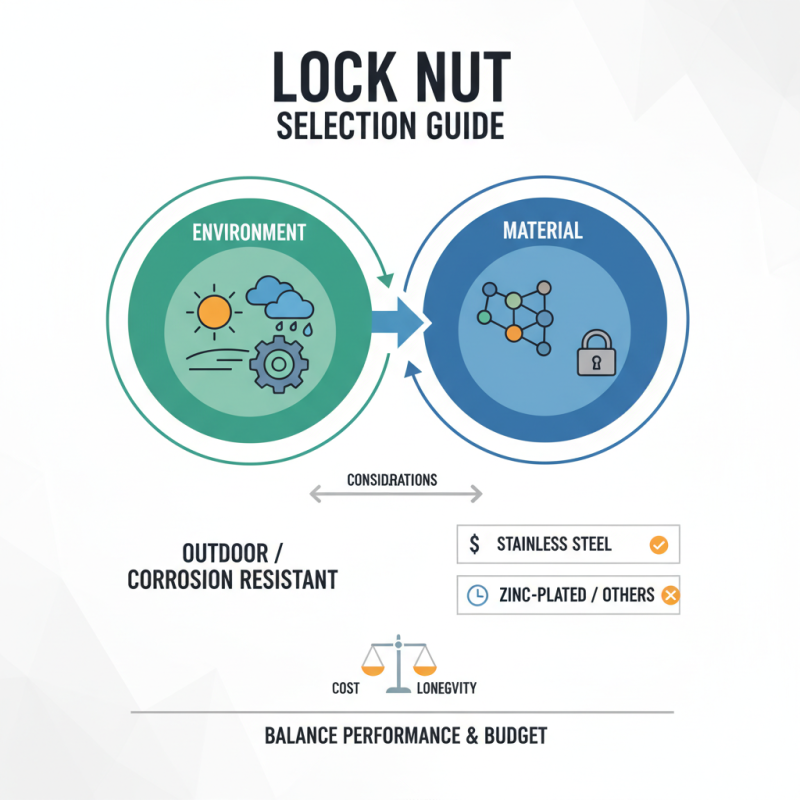

When selecting lock nuts for your projects, several key factors must be considered. The type of environment plays a crucial role. If the project is outdoors, choose materials that resist corrosion. Stainless steel is often a go-to choice for such situations. However, it can be more expensive. Weigh the material cost against project longevity.

Thread compatibility is another critical aspect. Lock nuts need to fit the bolts securely. An incorrect size can compromise the entire assembly. Testing different nuts on the bolts can help you find the right match. Sometimes, it feels tedious, but this step is essential to ensure safety.

The load requirements of your project also matter. Some lock nuts are designed for heavy loads, while others are suitable for lighter tasks. Misjudging this can lead to failures. Look into the specifications and ratings before making a choice. Revisiting your decisions at this point might save time and resources later. Understand that no selection process is perfect; adaptability is key in engineering.

When selecting lock nuts for your projects, it is essential to understand industry standards and specifications. Lock nuts are crucial for ensuring that fasteners remain secure under various conditions. There are several types of lock nuts, such as nylon insert, prevailing torque, and serrated flange. Each type serves a specific purpose and has unique characteristics.

Pay attention to material standards. Stainless steel is popular for its corrosion resistance. However, it may not be suitable for extreme temperatures. On the other hand, carbon steel offers strength but lacks the same protection. Make sure your choice aligns with the environmental conditions your project will face. Consider factors like load strength and vibration resistance as well.

It can be challenging to choose the right lock nut. Some projects require a fine-tuned specification, while others may offer flexibility. This complexity often leads to trial and error. Always have a backup plan if your initial choice does not hold up. Be prepared for adjustments and learn from your experiences to refine your future selections.

| Lock Nut Type | Material | Standard Specification | Common Applications | Torque Specifications |

|---|---|---|---|---|

| Hex Lock Nut | Steel | ASTM A194 | Machinery, Equipment Assembly | 25-30 ft-lbs |

| Nylon Insert Lock Nut | Stainless Steel | ANSI B18.2.2 | Automotive, Appliance | 20-25 ft-lbs |

| Jam Nut | Carbon Steel | ISO 7040 | General Use, Construction | 15-20 ft-lbs |

| Cap Nut | Aluminum | ASME B18.2.2 | Furniture, Decorative Applications | 10-15 ft-lbs |

| Castle Nut | Alloy Steel | MIL-N-25027 | Automotive, Heavy Machinery | 30-35 ft-lbs |

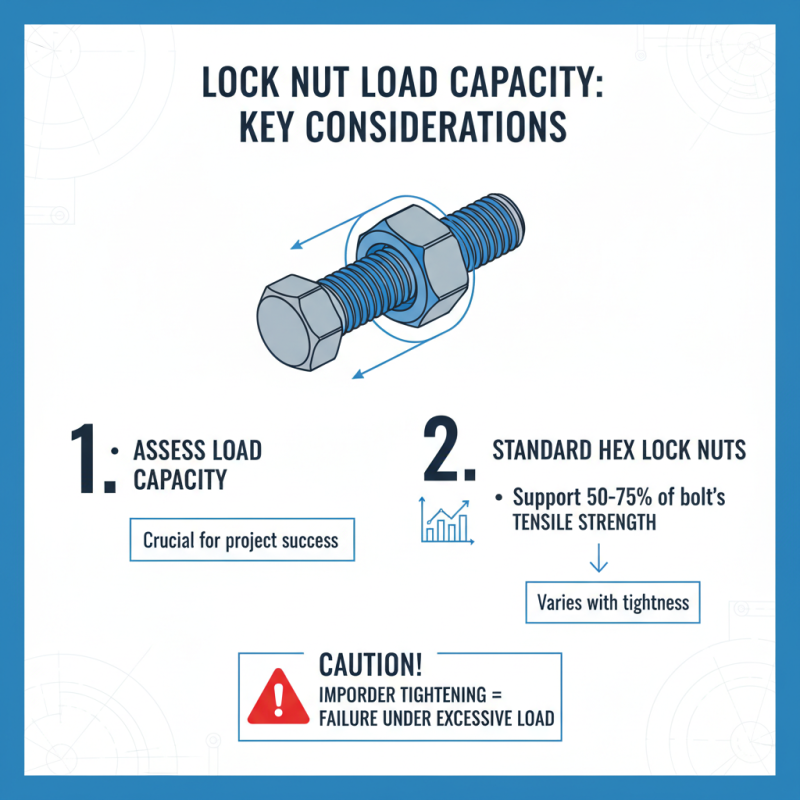

When selecting lock nuts for your projects, assessing load capacity is crucial. Lock nuts can bear various loads based on their design and material. For example, according to a recent engineering report, a standard hex lock nut can support loads ranging from 50% to 75% of the tensile strength of the bolt used. This variation depends on how tightly the nut is secured. If not done properly, the nut may fail under excessive load.

Material compatibility also plays a significant role in the longevity of lock nuts. Steel lock nuts may not endure corrosive environments as well as those made from stainless steel or polymer. A study indicated that using appropriate materials could enhance the lifespan of fasteners by up to 30%. This means choosing the right material is not just about strength, but also about durability in specific applications.

Consider special situations like high-temperature environments. Standard lock nuts may deform or lose effectiveness. Assessing the environment where the lock nuts will be used is key. Failing to consider the factors might lead to unexpected failures in projects. Proper analysis leads to better outcomes in fastener selection.

Lock nuts are crucial in engineering projects for securing components. When installing lock nuts, ensure you follow best practices for optimal performance. Proper torque application is vital. Too loose, and they may come undone. Too tight, and it could damage the thread or the material.

Tips for installation: Always clean the threads before installation. Dirt and debris can affect the locking mechanism. Align all components properly before tightening. Missalignment can lead to uneven wear and potential failure. Remember, the right environment matters too. Extreme temperatures can affect the materials used in lock nuts.

Maintenance is essential to avoid issues. Regularly check for signs of wear or corrosion. If a lock nut appears damaged, replace it immediately. Do not wait for failure. Use anti-seize compounds if applicable. This can help in preventing galling and make future disassembly easier. Always keep a spare set on hand. This small step can save time and effort during repairs.

This bar chart illustrates the distribution of different types of lock nuts used in various engineering projects, showcasing the prevalence of steel and stainless steel lock nuts compared to other materials.