Inquiry

Form loading...

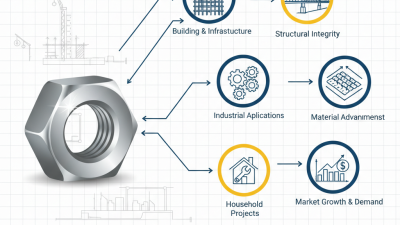

In the realm of construction and manufacturing, the significance of fasteners cannot be overstated, with hex nuts being a pivotal component in various applications. According to John Anderson, a leading expert in the fastener industry, "Hex nuts are essential for creating robust connections that can withstand the rigors of both structural and mechanical loads." These six-sided fasteners are not only versatile but also provide superior locking capabilities when paired with corresponding bolts, making them a staple in assembling machinery, fixtures, and frameworks.

In both residential and industrial contexts, understanding the properties and proper usage of hex nuts is crucial for ensuring safety and reliability. The design of a hex nut allows for easy gripping with a wrench, facilitating effective torque application during installation. As projects grow in complexity, the demand for reliable fasteners like hex nuts continues to rise, reinforcing their role as unsung heroes of construction and manufacturing processes.

Overall, the integration of hex nuts into engineering designs underscores their importance in achieving structural integrity and operational efficiency. By delving into the various types of hex nuts available and their specific applications, professionals can ensure that they select the most appropriate fastener for their needs, ultimately leading to successful and enduring projects.

Hex nuts are essential fasteners widely used across construction and manufacturing industries. Defined as a six-sided polygon, hex nuts are typically made from materials such as steel, stainless steel, brass, and plastic, which provide strength, durability, and resistance to various environmental conditions. According to the Global Fastener Market Report, hex nuts account for approximately 25% of the total demand for fasteners due to their versatility and robustness.

One of the defining features of hex nuts is their standardized threading, which allows them to securely couple with bolts or screws of matching size. This compatibility ensures that they provide stable connections in structures ranging from residential buildings to heavy machinery. The Mechanical Fastening Industry's Annual Review highlights that the ability to withstand tensile and shear stress makes hex nuts a critical component in load-bearing applications. Furthermore, the prevalence of hex nuts in applications such as automotive assembly, industrial machinery assembly, and construction projects signifies their importance in ensuring structural integrity and safety in various industries.

This chart illustrates the distribution of hex nut applications across various industries in construction and manufacturing. The data shows the percentage usage of hex nuts in several key sectors.

Hex nuts are essential fasteners used in a variety of construction and manufacturing applications. The most common types include standard hex nuts, flanged nuts, lock nuts, and wing nuts. Standard hex nuts are versatile and have a hexagonal shape allowing for easy manipulation with tools. According to a recent industry report by the Fastener Industry Coalition, standard hex nuts account for approximately 40% of all fasteners used in construction, highlighting their significance in securing components in both structural and mechanical assemblies.

Flanged nuts, which feature a circular flange beneath the nut, provide a larger surface area for load distribution and are particularly beneficial in reducing the risk of damage to softer materials. The growing trend towards using heavier materials in construction has increased the demand for these nuts, as they help in maintaining integrity under stress.

Lock nuts, on the other hand, are designed to resist unintentional loosening due to vibration. A report from the Global Fasteners Market indicates that the demand for lock nuts is projected to grow at a CAGR of 5.4% over the next five years, driven by their importance in high-stress applications typically found in automotive and industrial machinery.

Wing nuts, characterized by their distinct "wings", allow for hand-tightening, making them ideal for quick adjustments and assembly, especially in temporary structures or setups. Their unique design is conducive to rapid application in environments where tools may be limited. The increasing innovation in fastening technology fuels the growth of hex nut varieties, as manufacturers are constantly seeking improved performance and reliability in their applications, with a focus on enhancing safety and efficiency in construction and manufacturing processes.

Hex nuts are fundamental fasteners widely utilized across various industries, playing a critical role in construction and manufacturing. According to a market analysis report by Research and Markets, the global hex nut market is expected to grow significantly, with an anticipated CAGR of 5.4% from 2021 to 2026. This growth is primarily driven by the increasing demand for robust and reliable fastening solutions in diverse applications, ranging from automotive assembly to building frameworks.

In construction, hex nuts are essential for securing structural steel connections, ensuring stability and safety in buildings and bridges. Their versatile design allows for compatibility with different bolt sizes, making them essential in scaffolding and heavy machinery assembly. The construction industry alone contributes to approximately 40% of the total demand for hex nuts, as highlighted in a report by the International Fastener Association. Similarly, in manufacturing, hex nuts are integral to machinery equipment and appliances, where they aid in forming secure joints capable of bearing substantial loads, ultimately enhancing the durability and reliability of manufactured products. As industries increasingly prioritize efficiency and structural integrity, hex nuts remain a pivotal component in achieving these objectives.

| Industry | Application | Material Used | Size Range | Common Standards |

|---|---|---|---|---|

| Construction | Joining structural components | Steel, Stainless Steel | M3 to M30 | ASTM A563, ISO 4032 |

| Automotive | Wheel assembly | Carbon Steel, Alloy Steel | M5 to M20 | SAE J995, ISO 3764 |

| Manufacturing | Equipment assembly | Aluminum, Brass | M2 to M25 | DIN 934, ANSI/ASME B18.2.2 |

| Aerospace | Fastening components on aircraft | Titanium, Steel | M4 to M16 | AMS 1965, ASNA 807 |

| Electronics | Mounting circuits and panels | Plastic, Stainless Steel | M1 to M10 | IPC-A-610, ISO 9001 |

When it comes to installation and maintenance of hex nuts in construction and manufacturing, understanding best practices is essential to ensure structural integrity and reliability. Hex nuts are commonly used fasteners that play a critical role in assembling components, and ensuring they are installed correctly can prevent failures. According to the American National Standards Institute (ANSI), proper tightening methods should be employed to reach the optimal torque levels, typically measured in foot-pounds. This ensures that the assembly is secure and minimizes the risk of loosening over time due to vibrations and environmental factors.

Maintenance of hex nuts is just as important as the initial installation. Regular inspections should be part of every maintenance program, particularly in heavy machinery and structural applications. A study published by the International Journal of Engineering Research indicates that loose fasteners can lead to catastrophic failures, highlighting the necessity of periodic checks. Utilizing torque wrenches calibrated for precision can aid in maintaining the required tension on hex nuts, and applying appropriate locking mechanisms, like lock washers or thread-locking compounds, can enhance their reliability.

**Tips:** Always refer to the manufacturer's specifications for appropriate torque values to avoid over-tightening, which can damage the materials being fastened. Additionally, consider environmental factors that may affect the performance of hex nuts, such as temperature changes and exposure to chemicals. Regularly scheduled maintenance checks can mitigate potential issues before they escalate into costly repairs.

Hex nuts are essential components in construction and manufacturing, providing a reliable means of fastening various structural elements. Their six-sided design allows for easy gripping and torque application using standard tools, making them a popular choice in assembling frameworks, machinery, and various assemblies. One of the primary advantages of hex nuts is their ability to maintain structural integrity. When properly secured, they create a strong connection that can withstand significant loads and stresses, which is vital in ensuring the stability of buildings and infrastructure.

In addition to their strength, hex nuts contribute to security in construction settings. They can be used in conjunction with washers and bolts to distribute load and prevent loosening over time due to vibration or environmental factors. This resistance to loosening is crucial in environments subject to dynamic forces, such as bridges or machinery in industrial applications. Additionally, the availability of various materials and coatings for hex nuts allows them to be tailored to specific environments, enhancing their resistance to corrosion and wear. This versatility makes hex nuts an indispensable component in ensuring the longevity and safety of constructed projects.