Chemical Anchor Bolts

Chemical Anchor Bolts - Premium Structural Fastening Solution

Chemical anchor bolts are advanced construction fasteners designed to create high-strength, permanent bonds in concrete and masonry substrates. Utilizing a two-component epoxy or vinyl ester resin system, these anchors provide superior load-bearing capacity and long-term durability for critical structural applications.

fitting Socket

Our high-performance fitting sockets are engineered to provide secure and durable anchor points in concrete structures, designed for seamless integration with various construction elements. These premium cast-in sockets serve as reliable connection interfaces for post-installed steel components, façade systems, and structural supports.

Wave anchor

Precision-engineered for superior load transfer and structural integrity, our wave anchors are high-performance embedment solutions designed to create secure connections between concrete structures and secondary components. The unique wave-shaped design enhances mechanical interlocking with concrete, ensuring optimal load distribution and resistance to pull-out forces.

Manufactured from heavy-duty, corrosion-resistant materials with optional galvanized or, these anchors excel in commercial construction, infrastructure projects, and industrial applications. Their pre-weldable base plates and customizable configurations simplify installation while maintaining strict compliance with international building standards.

Wave Anchors are high-performance embedded fixings designed to provide secure, durable connections in concrete and masonry structures. Engineered for versatility, these anchors are ideal for a wide range of applications across construction and infrastructure projects.

Ferrules, Sleeves, lifting sockets with cross hole, Threaded Tube lifting sockets,Precast Construction Accessories

The Ferrule base corresponds to the dimensions and load levels of the spherical head anchors.

An adapter can be screwed onto the anchor foot thread for recessed installation in the component.

can be screwed onto the anchor base thread. The adapter can take the shape of the spherical head anchor head or another load other load-bearing means, such as the threaded sleeve with threads on both sides, etc. etc. The idea behind this is that when the extension adapter is removed from the anchor base the “Ferrule” remaining permanently in the component is deep in the concrete and, if the opening is grouted, the “Ferrule” is protected from water. “Ferrule ” is protected from water and therefore cannot rust or damage the component. Adapters and accessories are available on request.

Capstan lifting Anchor,Foot Anchor,Construction systems,Precast Concrete Double Head Lifting Foot Anchor

Capstan lifting anchors are used in concrete applications. These anchors are widely employed in the precast concrete industry to facilitate the lifting and handling of various concrete elements, such as pipes, slabs, and thinner, tile-like components. Capstan anchors are embedded into concrete elements during the casting process. They are designed to provide secure attachment points for lifting equipment, ensuring safe and efficient handling. The system often includes additional tools, such as pocket formers made of rubber, steel, or magnets, which create recesses in the concrete for the anchors. Capstan anchors are available in various types and load capacities to accommodate different project requirement. For instance, load groups can range from 1.3 tons to 32 tons, with options for black or galvanized finishes. In summary, capstan lifting anchors are essential components in precast concrete construction, offering a versatile, efficient, and safe solution for lifting and handling cone elements

Heavy-duty utility anchors,Utility anchors,Utility Lifting anchors

The Utility Anchor System represents a strategically engineered solution, meticulously crafted to streamline and economize the critical processes of lifting and maneuvering precast concrete components. Its inherent economic advantages, coupled with its intuitive ease of operation and broad spectrum of versatility, are poised to significantly enhance the efficiency of any precast concrete production facility. This system empowers precast operators to execute a comprehensive array of handling tasks, encompassing the initial extraction of precast elements from their molds, the subsequent manipulation of these elements within the precast yard, the secure loading of materials for transportation, and the final stages of unloading and precise placement at the construction site. A key advantage of the Utility Anchor System lies in its elimination of the need for specialized lifting apparatus or proprietary hardware.

Our heavy-duty utility anchors are designed to deliver unmatched structural stability and load-bearing performance in construction applications. Manufactured from high-strength, corrosion-resistant steel with hot-dip galvanized/zinc-plated finishes, these ASTM-compliant cast-in anchors provide reliable embedded connections for:

- Structural steel framing systems

- Curtain wall installations

- Mechanical equipment mounting

- Precast concrete assemblies

- Bridge and infrastructure projects

Rubber Formers for Construction Embedment,Rubber Recess Former for Lifting Precast Concrete Anchor

A rubber former is a specialized, reusable mold made from flexible rubber materials such as polyurethane, natural rubber, or silicone. It is widely used in the construction industry, especially in precast and cast-in-place concrete applications. Rubber formers create precise recesses, cavities, or decorative patterns in concrete structures, ensuring high accuracy and ease of removal compared to traditional wooden or metal molds.

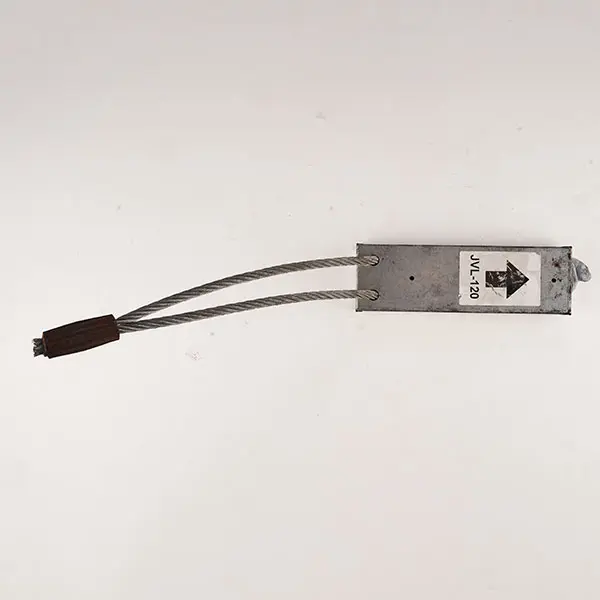

Connection Wire Loop Box, Precast wall connection loop box for building construction

Precision-engineered for modern construction needs, our Loop Box embedments provide reliable and efficient anchoring solutions for concrete structures. Designed as prefabricated cast-in units, these high-strength galvanized steel assemblies ensure secure connections for post-installed elements while maintaining structural integrity.

Lifting Loops, Precast concrete lifting system, Wire lifting Loops, Cable lifting loops, Wire rope lifting

Our lifting loops are high-strength structural anchors engineered for secure load transfer in concrete and masonry applications. Manufactured from galvanized or stainless steel, these durable embedded components provide reliable anchoring points for lifting, rigging, and structural connections during construction and throughout a building's lifecycle.

Cast-in lifting insert, Lifting sockets, Flat end sockets, Precast Construction, Fixing inserts

A **cast-in lifting insert** is a high-strength, engineered component designed to provide reliable anchorage points for lifting, handling, and positioning precast concrete elements during construction. Manufactured from robust materials such as hot-dipped galvanized steel or stainless steel, these inserts are permanently embedded into concrete during the casting process, ensuring seamless integration and optimal load transfer.

Bolt anchor, bolt sleeve, lifting anchor, allround anchor

For the secure lifting of planar concrete elements via face-mounted installations, the Bolt Anchor presents a specialized solution, particularly advantageous when embedded reinforcement is absent. This anchor system is meticulously engineered to handle lighter load applications, offering a range of threaded connections spanning from Rd 12 to Rd 30. Should project demands necessitate the manipulation of heavier loads, the Allround Anchor short provides a robust alternative, leveraging an identical concrete anchoring methodology to that of the Bolt Anchor. To cater to diverse environmental conditions, the Bolt Anchor is offered in two distinct configurations: a standard variant featuring a zinc-coated socket for general applications, and a premium version equipped with a corrosion-resistant stainless steel socket, specifically designed to provide enhanced durability in aggressive environments. This dual-option approach ensures that the Bolt Anchor can be tailored to meet the specific requirements of a wide array of construction projects, balancing load capacity with environmental resilience."