Customized Expansion Shell Anchorage

Key Advantages

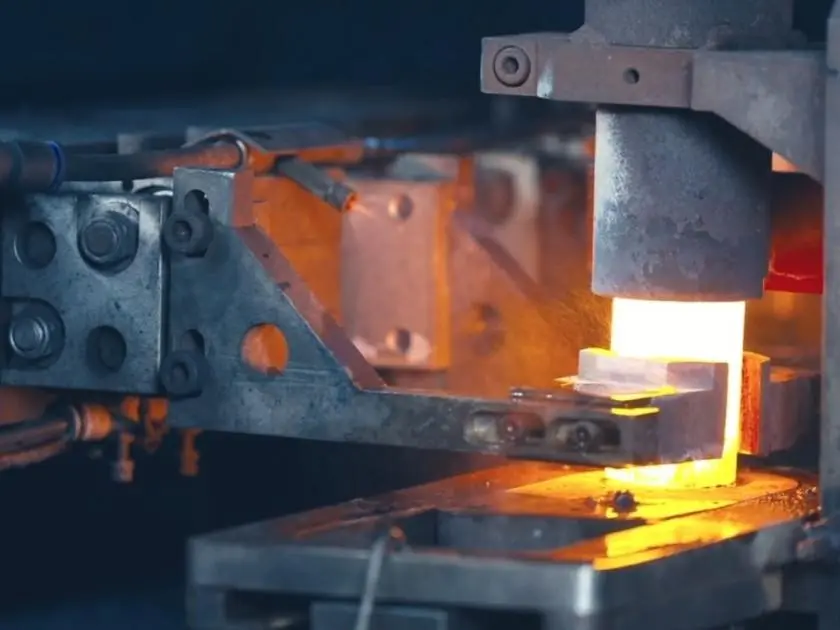

Robust Construction: The use of forged components enhances mechanical strength, ensuring high resistance to wear, deformation, and extreme loads. This guarantees long-term stability in underground support applications.

Fast and Flexible Installation:Designed for efficiency, the system allows for adjustable lengths and spacing, enabling rapid deployment and reducing labor-intensive setup times.

Superior Anchoring and Tensioning:The system provides firm, secure support even in high-vibration and heavy-load conditions, enhancing the overall stability of mining structures.

How It Works

The expansion shell is a simple yet highly effective anchoring solution. When the bolt is rotated within a pre-drilled hole, the shell expands outward, tightly gripping the surrounding rock. This expansion generates high tension at the borehole base, effectively transferring load forces from the bolt head and plate directly to the rock. The result is immediate and secure reinforcement, critical for maintaining the integrity of tunnels, shafts, and rock formations in mining and excavation sites.

Applications

Tunnel Reinforcement:Strengthens underground passageways, preventing collapses and ensuring long-term structural stability.

Rock Face Stabilization:Secures loose rock formations, minimizing the risk of falls and maintaining safer working conditions.

Load-Bearing Ground Support:Anchors essential mining structures, distributing loads effectively across challenging geological formations.

Quality Assurance

Each expansion shell anchorage system undergoes strict quality checks for strength, dimensional accuracy, and performance. We provide detailed inspection reports with every batch, ensuring consistent quality and peace of mind.

With its durable construction and high performance, our expansion shell anchorage system is a trusted solution for securing stability in challenging geological conditions.

|

Product Name |

Expansion Shell Anchorage |

|

Material |

Steel Alloys, Carbon Steel, Aluminum, Brass, Bronze, ect |

|

Size |

Customized |

|

Surface |

Customized |

|

Production Process |

Casting, CNC Machining |

|

Package |

Carton & Pallet |

|

Quality Control |

100% inspection |

|

Usage Scenarios |

Mining, Bridge, Building |

Product Services

1.After-sales quality control: After finished product inspection, ensure that it meets customer requirements.

2.Cooperation services: We can provide customers with OEM and ODM services to customize products to ensure that customer requirements are met.

Sign up for our newsletter

We are Weiye Group, an innovative and dynamic company with over three decades of experience in the manufacturing sector.