Hanger Bolt

Standards

Hanger bolts are manufactured under various international standards, including:ANSI/ASME B18.12 (U.S. standard for hanger bolts)

DIN 693 (German/EU standard)

ISO 1478 (International thread standards for wood screws)

Materials

|

Material |

Properties |

Common Uses |

|

Carbon Steel |

Economical, strong |

Indoor furniture, general construction |

|

Stainless Steel (304/316) |

Corrosion-resistant |

Outdoor, marine, or high-moisture environments |

|

Zinc-Plated Steel |

Moderate rust resistance |

Indoor/light outdoor use |

|

Brass |

Decorative, corrosion-resistant |

Architectural & aesthetic applications |

Applications of Hanger Bolts

Hanger bolts are versatile fasteners widely used in industries requiring secure wood-to-metal connections. Their unique dual-thread design makes them ideal for:1.Furniture Manufacturing & Assembly

Table/Chair Construction: Securing wooden legs to metal frames or plates

Cabinet Hardware: Mounting hinges, handles, and brackets to wooden surfaces

Modular Furniture: Connecting prefabricated wood and metal components

2. Construction & Carpentry

Structural Brackets: Attaching wooden beams to steel supports

Deck Building: Fastening railings and posts to metal anchors

Staircase Assembly: Joining wooden treads to metal stringers

3. Industrial & Machinery

Equipment Mounting: Installing machines with wooden bases to metal floors

Tool Stands: Securing wood benches to metal frames

Conveyor Systems: Fastening wooden guides to metal structures

4. Hanging & Suspension Systems

Swing Sets: Connecting chains/ropes to wooden beams

Heavy Shelving: Mounting brackets to wooden studs

Retail Displays: Hanging signs from wooden ceilings

5. Automotive & Marine

Vehicle Interiors: Attaching wood trim to metal frames

Boat Carpentry: Securing wooden panels to aluminum hulls

6. DIY & Home Improvement

Garage Storage: Hanging tools/organizers on wooden walls

Playground Equipment: Assembling jungle gyms and climbing structures

Advantages of Hanger Bolts

Hanger bolts offer unique advantages that make them indispensable for wood-to-metal fastening in construction, furniture, and industrial applications. Here’s why they stand out:1. Dual-Function Design

✅ Wood Thread End:

Self-tapping coarse threads bite deeply into wood, providing superior pull-out resistance compared to screws or nails.

Eliminates the need for pre-threaded holes (though pilot holes are recommended for hardwoods).

✅ Machine Thread End:

Compatible with nuts, washers, or tapped metal parts, enabling adjustable tension and disassembly.

Allows use of locknuts (e.g., Nyloc) to prevent loosening from vibrations.

2. Strong & Reliable Connection

✔ Higher Load Capacity: The wood thread distributes stress over a larger area than standard screws, reducing wood splitting.

✔ No Weak Points: Headless design avoids stress concentration at the head (unlike traditional bolts).

✔ Vibration Resistance: Machine thread end secures tightly with a nut, ideal for dynamic loads (e.g., machinery, playground equipment).

3. Versatility Across Materials

Works with wood, plywood, MDF, particleboard, and metal.

Compatible with stainless steel, zinc-plated, or brass hardware for corrosion resistance.

4. Concealed & Aesthetic Fastening

✔ No Visible Head: Creates a clean, professional look in furniture and cabinetry.

✔ Flush Installation: Sits entirely within materials (unlike bulky hex-head bolts).

5. Easy Installation Options

Wrench/Grip Method: Rotate the smooth midsection with pliers or a wrench.

Double-Nut Technique: Thread two nuts onto the machine end and tighten to drive the wood thread in.

Specialty Drivers: Hex or square-drive variants available for power tools.

6. Cost & Time Efficiency

Faster than alternatives (e.g., drilling+tapping separate holes for bolts).

Eliminates extra hardware (no need for separate screws and nuts).

Materials

|

Product Name |

Hanger Bolt |

|

Material |

carbon steel,Zinc-Plated Steel ,stainless steel,brass, |

| Size |

Metric Sizes:M4 – M12 Imperial Sizes:#8 – 1/2" Common Sizes: Metric: M6x30mm, M8x40mm, M10x50mm Imperial: 1/4"-20 x 1.5", 5/16"-18 x 2" |

|

Surface |

Plain, black,zinc plated,Hot Dip Galvanized,passivated,Chrome/Nickel Plating |

|

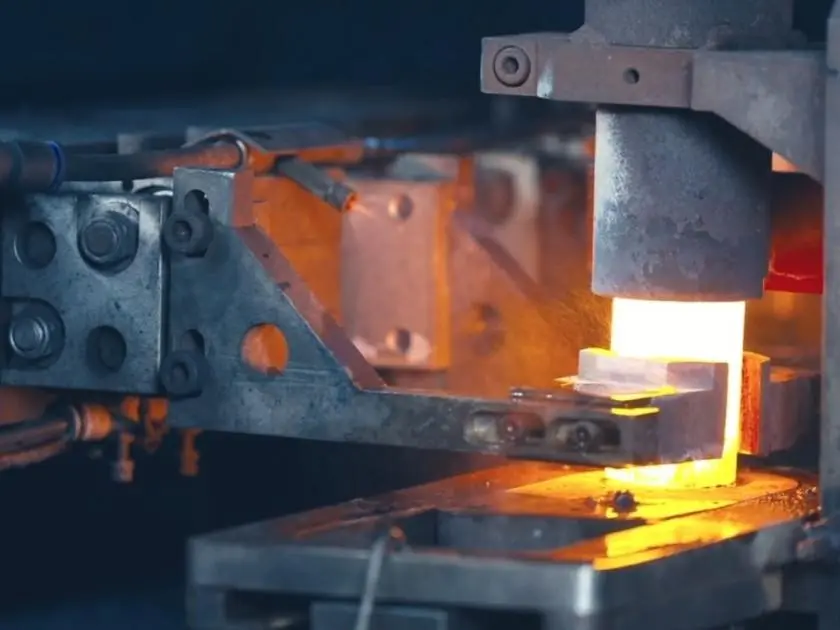

Production Process |

Forging |

|

Threads |

Metric Coarse/Fine & Imperial UNC, UNF |

|

MOQ |

800KG |

|

Package |

Carton & Pallet |

Product Services

1.After-sales quality control: After finished product inspection, ensure that it meets customer requirements.

2.Cooperation services: We can provide customers with OEM and ODM services to customize products to ensure that customer requirements are met.