Heavy Duty Roller Assembly, Tie Down Dock Roller Assembly

Description

1.Material Composition:

Carbon Steel Base: Fabricated from high-strength carbon steel (e.g., ASTM A36 or AISI 1045), offering superior load-bearing capacity and structural stability. The base is often hot-dip galvanized or coated with epoxy to resist corrosion in saltwater environments.

Rubber Roller: Made of durable, marine-grade synthetic rubber (e.g., nitrile rubber/NBR or neoprene) with high UV resistance, seawater compatibility, and abrasion resilience. Shore hardness typically ranges from 60A to 85A to balance grip and flexibility.

304 Stainless Steel Split Pins (Cotter Pins): Used for securing roller shafts and critical connections. Grade 304 stainless steel provides excellent corrosion resistance, ensuring long-term reliability in humid and saline conditions.

2.Standards & Certifications:

Carbon Steel: Complies with ASTM A36/AISI 1045 for mechanical properties and ISO 1461 (hot-dip galvanizing standards).

Rubber Rollers: Meets ISO 4649 (abrasion resistance) and ASTM D2000 (chemical stability).

304 Split Pins: Manufactured to DIN 94 or ISO 1234, with material certification per ASTM A276/A479 (stainless steel specifications).

Marine Compliance: Certified by DNV-GL, ABS, or Lloyd’s Register for marine applications.

3.Surface Treatments:

Hot-dip galvanizing or epoxy coating for rust prevention in coastal or offshore applications.

Passivation for stainless steel components to enhance corrosion resistance.

4.Applications:

Shipbuilding & Dry Docks: Transporting steel plates, hull sections, and prefabricated modules.

Port Infrastructure: Handling concrete caissons, breakwater armor stones, and piling systems.

Offshore Platforms: Supporting pipeline deployment, equipment movement, and tidal energy installations.

tidal energy installations. Marine Launch Systems: Guiding vessels during launch/retrieval operations.

Primary Uses:

Heavy Load Transfer: Safely move bulky, irregularly shaped materials (e.g., boulders, steel beams) in wet or uneven terrain.

Alignment & Stability: Ensure precise positioning of marine components during assembly.

Shock Absorption: Rubber rollers dampen vibrations and reduce impact forces on sensitive structures.

Product Information

|

Product Name |

Heavy Duty Roller Assembly(Tie Down Dock Roller Assembly ) |

|

Material |

carbon steel,stainless steel,rubber |

|

Size |

266x52x76mm |

|

Surface |

Hot Dip Galvanized,passivation,bare |

|

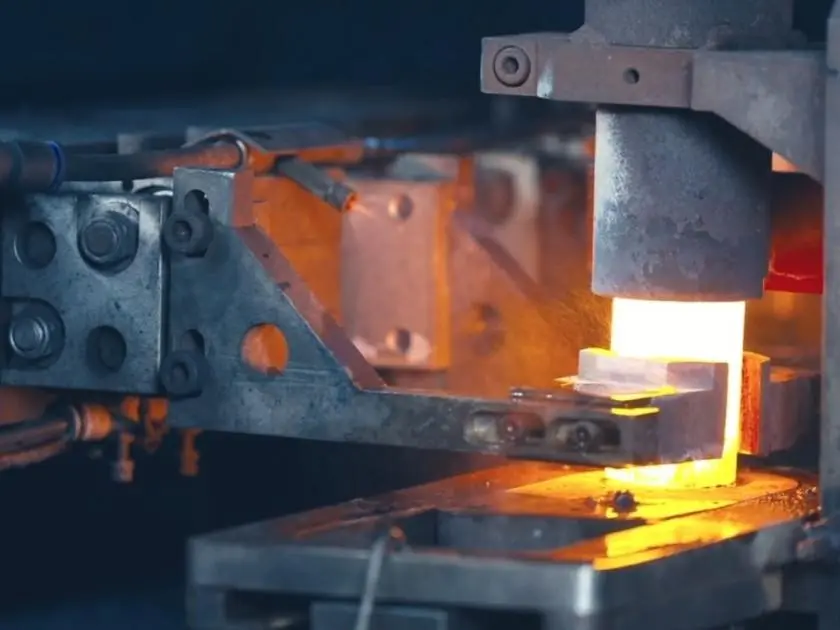

Production Process |

Stamping,welding |

|

MOQ |

800KG |

|

Package |

Carton & Pallet |

Product Services

1.After-sales quality control: After finished product inspection, ensure that it meets customer requirements.

2.Cooperation services: We can provide customers with OEM and ODM services to customize products to ensure that customer requirements are met.

Sign up for our newsletter

We are Weiye Group, an innovative and dynamic company with over three decades of experience in the manufacturing sector.