Hex Lag Screws

Standards

Complies with ASTM A307 Gr A, ASTM A449 (high-strength steel screws) and SAE J429 (mechanical properties).Materials

Carbon Steel:Common for general use, often coated for corrosion resistance.Stainless Steel (Grades 304/316): For outdoor or corrosive environments.

Hot-Dip Galvanized Steel: Enhanced rust resistance for heavy-duty applications.

Thread Types

Coarse Threads: For wood and soft materials.Fine Threads: Less common, used in metal-to-wood applications.

Applications

Structural wood connections (beams, decks, retaining walls).Heavy timber framing, utility poles, and outdoor projects.

Surface Treatments

Zinc Plating:Basic corrosion protection.Hot-Dip Galvanizing: Durable coating for harsh environments.

Ceramic Coatings: Heat and chemical resistance.

Classification

hex lag screws are available in two variations based on their head design: with a washer face and without a washer face. Here’s a detailed breakdown:1. Hex Lag Screws with Washer Face

Design: The hexagonal head includes an integrated, flat washer-like face beneath it. This design spreads clamping force over a wider area, reducing surface damage (e.g., wood splitting or metal deformation).

Applications: Ideal for direct installation into wood, metal, or composite materials without requiring a separate washer. Commonly used in structural projects like timber framing or decking.

Standards: Often comply with ASTM A449 or SAE J429 for load-bearing applications.

2. Hex Lag Screws without Washer Face

Design: The hexagonal head lacks an integrated washer, requiring a separate flat washer for installation.

Applications: Used when flexibility in washer selection is needed (e.g., thicker washers for soft materials or corrosion-resistant washers for harsh environments).

Standards: Compatible with the same material standards (e.g., stainless steel grades 304/316 or hot-dip galvanized coatings).

Key Differences

Load Distribution: Washer-face screws provide built-in load distribution, while non-washer-face types rely on added washers.Installation Efficiency: Washer-face screws save time by eliminating the need for a separate washer.

Material Compatibility: Non-washer-face screws allow customization (e.g., using nylon or copper washers for insulation or corrosion resistance).

Both types are widely used in construction, woodworking, and heavy-duty outdoor projects, with selection depending on structural needs and installation conditions.

Materials

|

Product Name |

hex lag screws |

|

Material |

carbon steel,stainless steel,Hot-Dip Galvanized Steel |

|

Strength |

ASTM A449 screws: Minimum yield strength of 92,000 psi (634 MPa). SAE J429 Grade 5: Yield strength of 92,000 psi (634 MPa). |

|

Size |

Diameter: 1/4" to 1" (imperial) or M6 to M24 (metric). Length: 1" to 12" (imperial) or 25 mm to 300 mm (metric). |

|

Surface |

Zinc Plating,Hot-Dip Galvanizing,Ceramic Coatings |

|

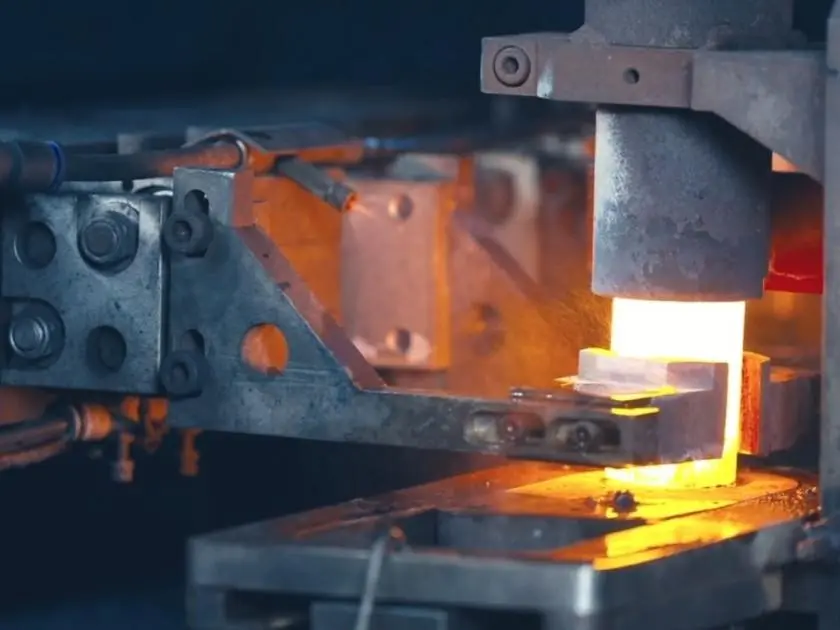

Production Process |

Forging |

|

Threads |

Metric Coarse/Fine & Imperial UNC, UNF, SAE, BSW |

|

MOQ |

800KG |

|

Package |

Carton & Pallet |

Product Services

1.After-sales quality control: After finished product inspection, ensure that it meets customer requirements.

2.Cooperation services: We can provide customers with OEM and ODM services to customize products to ensure that customer requirements are met.