Hex nuts, Hexagonal Nuts, Hex Nuts – Reliable, Durable, and Versatile Fastening Solutions

Product Information

Hex nuts are manufactured according to various international and industry-specific standards to ensure consistency, quality, and compatibility. Below are some of the most widely recognized standards for hex nuts:

1. ISO (International Organization for Standardization)

ISO 4032: Specifies the dimensions and tolerances for hex nuts with metric threads, ranging from M1.6 to M64. These nuts are commonly used in general engineering applications.

ISO 4033: Covers hex nuts with a higher height (thicker design) for applications requiring increased strength.

2. DIN (Deutsches Institut für Normung - German Institute for Standardization)

DIN 934: Defines metric hex nuts with standard dimensions and tolerances, widely used in Europe and other regions.

DIN 985: Specifies hex nuts with a nylon insert (lock nuts) to prevent loosening due to vibration.

3. ANSI/ASME (American National Standards Institute/American Society of Mechanical Engineers)

ANSI B18.2.2: Covers inch-series hex nuts, including dimensions, tolerances, and material requirements. These nuts are commonly used in the United States and other countries following the imperial system.

4. BS (British Standards)

BS 3692: Specifies the requirements for ISO metric precision hex nuts, including dimensions and mechanical properties.

5. ASTM (American Society for Testing and Materials)

ASTM A194: Covers heavy-duty hex nuts for high-pressure and high-temperature applications, often used with ASTM A193 bolts.

ASTM A563: Specifies carbon and alloy steel hex nuts for general-purpose and structural applications.

6. JIS (Japanese Industrial Standards)

JIS B 1181: Defines metric hex nuts, widely used in Japan and other Asian markets.

Key Features of Hex Nut Standards:

Thread Compatibility: Hex nuts are designed to match the thread pitch and diameter of corresponding bolts or screws.

Material Grades: Standards specify material properties, such as strength and corrosion resistance, to suit different applications.

Dimensional Tolerances: Precise dimensions ensure proper fit and performance in mechanical joints.

|

Product Name |

Hex nut |

|

Material |

Carbon steel,alloy steel,stainless steel,brass |

|

Strength |

Unified Hex Nut Strength Grades (ASTM A563 Gr.A,B,C,D), Carbon Steel: Most widely used, available in different grades (e.g., 4.8, 8.8, 10.9).Stainless Steel: Offers corrosion resistance and moderate strength (e.g., A2-70, A4-70). |

|

Size |

Metric: Dia M10-M64(Standard DIN 934 / ISO 4032) Imperial: Dia 3/16" – 2-1/4" |

|

Surface |

Plain, black,zinc plated,zinc yellow plated,Hot Dip Galvanized,passivated,Mechanical Galvanzied |

|

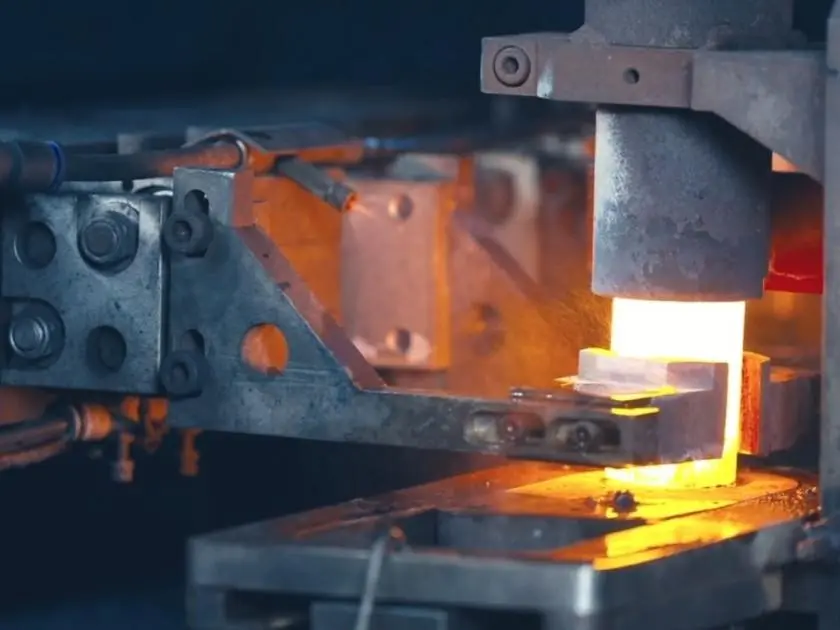

Production Process |

Forging |

|

Threads |

Metric Threads (ISO Metric), Unified Threads (UNC/UNF) , British Standard Whitworth (BSW), British Standard Fine (BSF), Pipe Threads (NPT/NPTF), Acme Threads |

|

MOQ |

800KG |

|

Package |

Carton & Pallet |

Product Services

1.After-sales quality control: After finished product inspection, ensure that it meets customer requirements.

2.Cooperation services: We can provide customers with OEM and ODM services to customize products to ensure that customer requirements are met.

Sign up for our newsletter

We are Weiye Group, an innovative and dynamic company with over three decades of experience in the manufacturing sector.