Hex Socket Head Cap Screw

Standards

Global Standards & Dimensional Compliance:ISO 4762 / DIN 912:> Metric series with head diameter = 1.5× nominal thread diameter (e.g., M8 head = 12 mm). Thread lengths follow 1×, 1.5×, or 2× diameter rules.

ASME B18.3 (Imperial): Unified thread series (e.g., 1/4"-20 UNC) with deeper hex sockets (0.050"–0.250" deeper than ISO) for ANSI-spec hex keys.

JIS B 1177: Japanese standard emphasizing reduced head height (0.8× diameter) and rounded socket edges to minimize crack initiation.

Materials

1.Carbon & Alloy SteelsMedium Carbon Steel: Cost-effective, general-purpose fastening (e.g., machinery, automotive).

Alloy Steel (e.g., 34CrMo4): Ultra-high strength for heavy-duty applications (construction, industrial equipment).

2.Stainless Steels

AISI 304/316: Corrosion-resistant for marine, food, and chemical environments.

17-4PH Stainless: High-strength, heat-treated for aerospace and medical devices.

3.Titanium Alloys

Ti-6Al-4V: Lightweight, biocompatible, used in aerospace and medical implants.

4.Nickel-Based Alloys

Inconel 718: Heat-resistant for extreme temperatures (jet engines, oil/gas industries).

High-Performance Polymers

5.Aluminum Alloys

7075-T6: Lightweight with moderate strength for drones and optical systems.

6.Copper Alloys

Beryllium Copper: Non-sparking, conductive for explosive environments and electrical systems.

Applications

Aerospace:Ti-6Al-4V HSCSs secure carbon-fiber reinforced polymer (CFRP) panels in aircraft wings, with fatigue limits exceeding 10⁷ cycles at 250 MPa R=0.1.

Medical Robotics:

M1.2 screws (Grade 12.9) with Parylene coating assemble surgical robotic arms, achieving 0.01 mm positional repeatability under sterilization.

Electric Vehicles:

Serrated flange HSCSs (DIN 6921) clamp battery busbars, maintaining contact resistance <0.5 mΩ under 50 N·m torque and thermal cycling (-40°C to 120°C).

Quantum Computing:

Gold-plated oxygen-free copper screws provide ultra-low electrical resistance (<0.001 Ω) in cryogenic superconducting circuits.

Advantages

1. High Torque TransmissionInternal Hex Drive: Allows precise torque application with minimal slippage, even in high-stress conditions.

Deep Socket Design: Distributes force evenly, reducing tool wear (e.g., ISO-compliant hex keys).

2. Space-Saving Profile

Low-Profile Head: Cylindrical head occupies minimal vertical space, ideal for compact assemblies (e.g., drones, microelectronics).

No Protruding Parts: Eliminates interference with adjacent components in densely packed systems.

3. Superior Strength-to-Size Ratio

High-Grade Materials: Alloy steel (e.g., 12.9 grade) achieves tensile strengths exceeding 1,200 MPa.

Optimized Thread Engagement: Full or partial threads reduce stress concentration points.

4. Corrosion Resistance

Material Versatility: Options include A4 (316) stainless steel, titanium, and coated alloys (e.g., Dacromet®).

Surface Treatments: Zinc-nickel plating or Xylan® coatings enhance durability in harsh environments.

5. Broad Standardization

Global Compliance: Adheres to ISO 4762, ASME B18.3, and JIS B 1177, ensuring interchangeability.

Metric/Imperial Options: Available in both measurement systems for cross-industry compatibility.

6. Vibration Resistance

Thread Locking Options: Compatible with adhesives (e.g., Loctite®) or serrated flanges (DIN 6921) to prevent loosening.

7. Thermal Stability

High-Temp Alloys: Inconel 718 retains strength at 700°C, suitable for jet engines or industrial furnaces.

Low-Temp Performance: Titanium screws function reliably in cryogenic environments (e.g., space applications).

8. Aesthetic Flexibility

Custom Finishes: Black oxide, anodized aluminum, or polished surfaces for visible assemblies (e.g., luxury automotive interiors).

9. Lightweight Solutions

Titanium/Polymer Options: Reduce weight by 40–60% compared to steel, critical for aerospace and medical devices.

10. Smart Integration

IoT-Enabled Variants: Embedded sensors monitor preload force or corrosion levels for predictive maintenance.

Materials

|

Product Name |

Hex Socket Head Cap Screw |

|

Material |

Carbon steel,alloy steel,stainless steel,brass,Titanium,Nickel-Based Alloys,Copper Alloys |

|

Size |

Metric Sizes: Standard Range: M1.6 to M64. Common Sizes: M3, M5, M8, M12, M16, M20. Imperial Sizes: Standard Range: #0 (0.060") to 1" diameter. Common Sizes: #4-40, 1/4"-20, 3/8"-16, 1/2"-13. Japanese Standard (JIS B 1177) Thread Diameter: M2 to M24. |

|

Surface |

Plain, black,zinc plated,Geomet,Electroless Nickel (ENP),Chrome Plating, Xylan™/PTFE Coating,Hot Dip Galvanized,passivated,Mechanical Galvanzied,Phosphate Coating,Chrome Plating,etc |

|

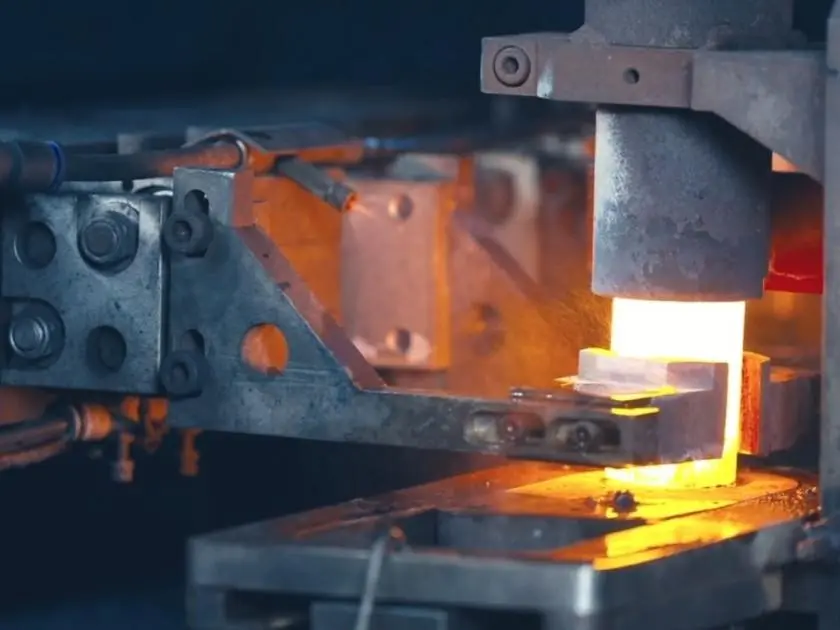

Production Process |

Forging |

|

MOQ |

800KG |

|

Package |

Carton & Pallet |

Product Services

1.After-sales quality control: After finished product inspection, ensure that it meets customer requirements.

2.Cooperation services: We can provide customers with OEM and ODM services to customize products to ensure that customer requirements are met.