LOCK NUTS

Product Information

Common types of lock nuts include:

Nylon Insert Lock Nuts: Feature a nylon ring that creates friction against the bolt threads, preventing unintentional loosening.

Metal Lock Nuts: Use deformed threads or integrated locking mechanisms to grip the bolt tightly.

Serrated Flange Nuts: Have serrations on the flange that bite into the surface, enhancing grip.

Lock nuts are manufactured according to various international and industry-specific standards to ensure their performance, reliability, and compatibility with corresponding bolts. Below are some of the most widely recognized standards for lock nuts:

1. ISO (International Organization for Standardization)

ISO 7040: Specifies prevailing torque type hex nuts (non-metallic insert, metric thread) with property classes 5, 8, and 10.

ISO 7042: Covers prevailing torque type all-metal hex nuts (metric thread) with property classes 8, 10, and 12.

2. DIN (Deutsches Institut für Normung - German Institute for Standardization)

DIN 985: Defines hex nuts with nylon inserts (metric thread) for general-purpose locking applications.

DIN 6927: Specifies flange nuts with non-serrated or serrated bases, which provide additional locking through surface grip.

3. ANSI/ASME (American National Standards Institute/American Society of Mechanical Engineers)

ANSI B18.16.3: Covers metric series prevailing torque lock nuts, including nylon insert and all-metal types.

ANSI B18.2.2: Includes inch-series lock nuts, such as nylon insert and metal lock nuts, for use in the United States and other regions following the imperial system.

4. BS (British Standards)

BS 3692: Specifies ISO metric precision hex nuts, including those with locking features.

5. ASTM (American Society for Testing and Materials)

ASTM A194: Covers heavy-duty lock nuts for high-pressure and high-temperature applications, often paired with ASTM A193 bolts.

ASTM A563: Includes carbon and alloy steel lock nuts for general-purpose and structural applications.

6. JIS (Japanese Industrial Standards)

JIS B 1181: Defines metric hex nuts, including those with locking features, widely used in Japan and other Asian markets.

Key Features of Lock Nut Standards:

Thread Compatibility: Lock nuts are designed to match the thread pitch and diameter of corresponding bolts.

Material Grades: Standards specify material properties, such as strength and corrosion resistance, to suit different applications.

Locking Mechanisms: Standards define the type of locking feature (e.g., nylon insert, deformed threads, serrated flange) and its performance requirements.

|

Product Name |

Lock nuts |

|

Material |

Carbon Steel,Stainless Steel,Brass,alloy steel. PA66(for Nylon) |

|

Strength |

Class 5,Class 8,Class 10,Class 12 |

|

Size |

Metric: Dia M2-M100 Imperial: 1/8 inch to 2 inches |

|

Surface |

Zinc Plating, Hot-Dip Galvanizing, Nickel Plating, Chromium Plating, Phosphate Coating, Black Oxide Coating, Dacromet Coating, Geomet Coating, Passivation, PTFE Coating (Teflon) |

|

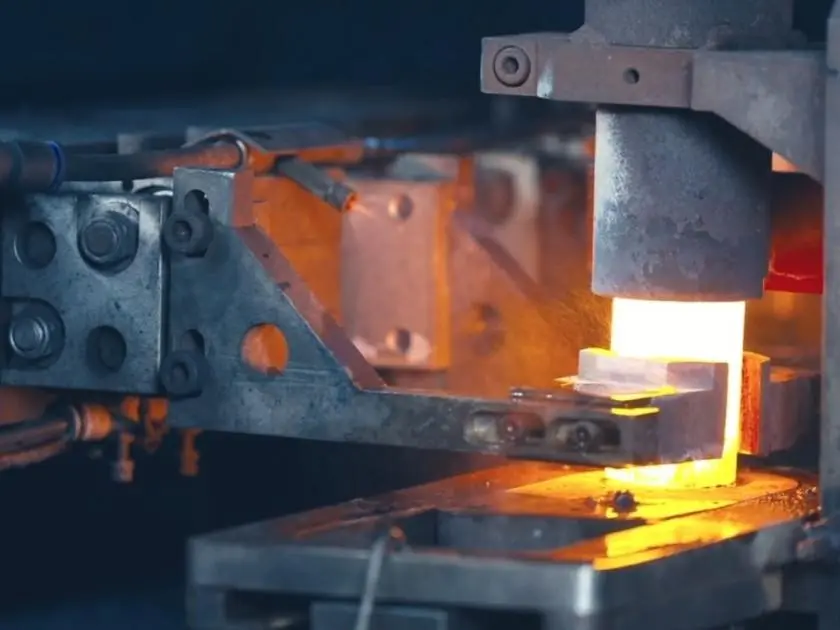

Production Process |

Forging |

|

Threads |

Metric Threads (ISO Metric), Unified Threads (UNC/UNF) , British Standard Whitworth (BSW), British Standard Fine (BSF), Pipe Threads (NPT/NPTF), Acme Threads |

|

MOQ |

1000KG |

|

Package |

Carton & Pallet |

Product Services

1.After-sales quality control: After finished product inspection, ensure that it meets customer requirements.

2.Cooperation services: We can provide customers with OEM and ODM services to customize products to ensure that customer requirements are met.

Sign up for our newsletter

We are Weiye Group, an innovative and dynamic company with over three decades of experience in the manufacturing sector.