Have You Selected the Right Square Head Machine Bolts for Secure Connections on Your Utility Poles?

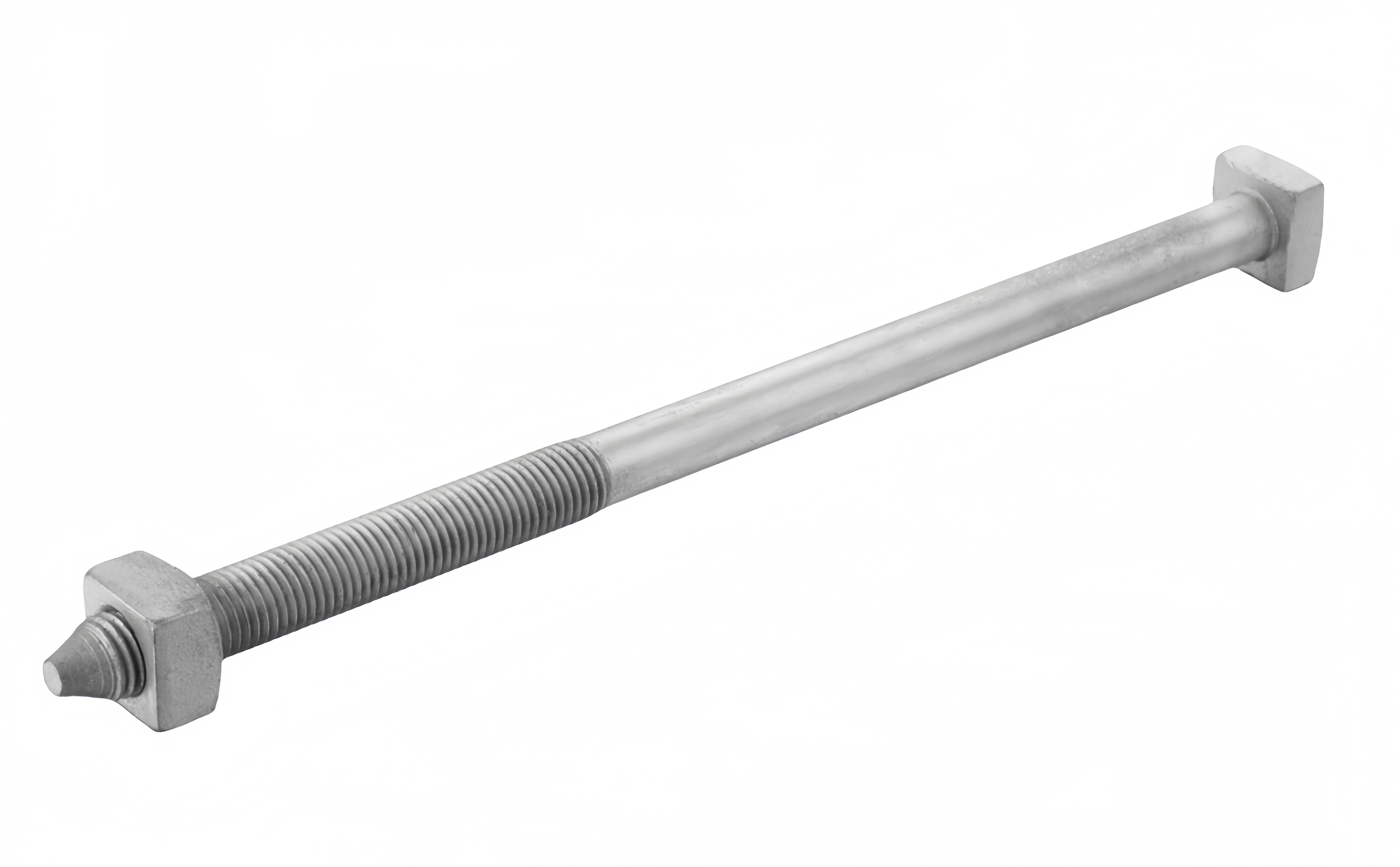

Safety starts with the right hardware. When you choose square head machine bolts for Utility Poles, you ensure secure and stable connections. These bolts offer excellent grip and durability. Focus on the correct size, material, and threading to prevent failures and keep your infrastructure reliable for years to come.

Key Takeaways

- Pick square head bolts for strong grip and toughness. They hold well, even in bad weather outside.

- Get the correct size and type of bolts. Hot-Dip Galvanized stops rust and lasts longer.

- Make sure the bolt threads fit the nut. This avoids loose parts and keeps utility poles steady.

Importance of Square Head Machine Bolts

Why Square Head Machine Bolts Are Ideal for Utility Poles

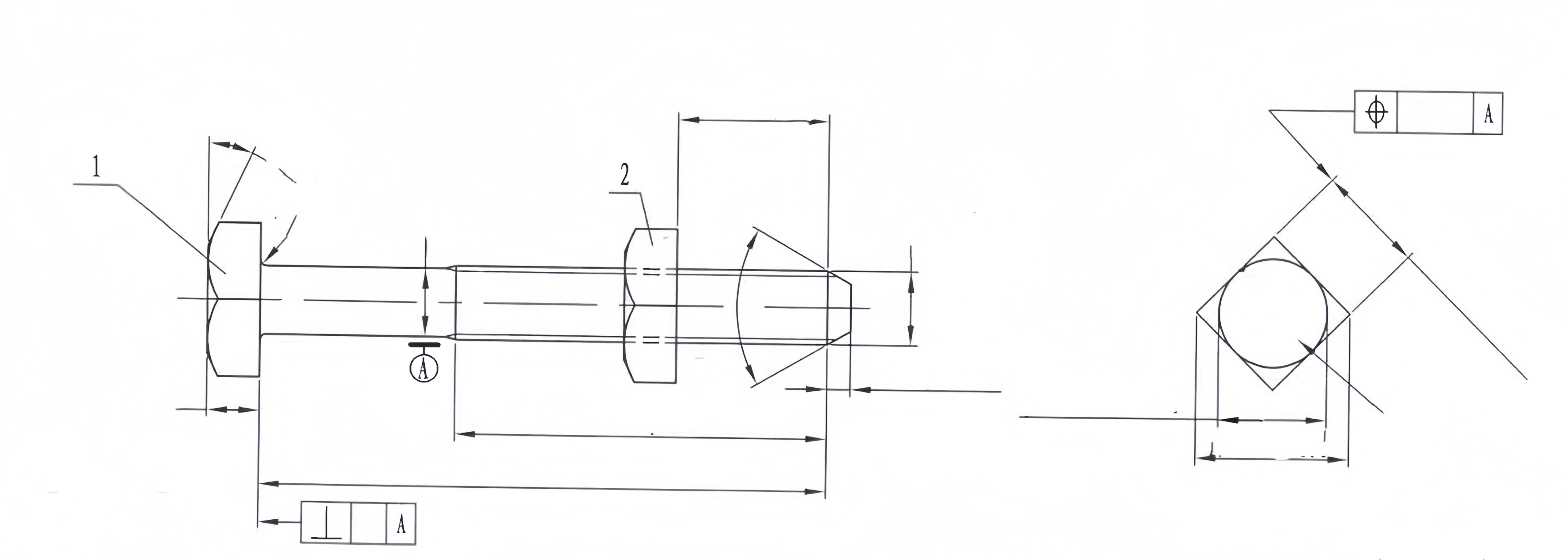

Square head machine bolts are a top choice for utility poles because of their unique design and functionality. The square head provides a larger gripping surface, making it easier to tighten or loosen the bolt, even in challenging conditions. This feature is especially useful when working with tools in outdoor environments where precision is critical.

These bolts also offer excellent durability. Made with a hot-dip galvanized Surface Finish, they resist corrosion and withstand harsh weather conditions.This ensures that your utility pole connections remain secure over time. Additionally, the threading on square head machine bolts allows for a tight and reliable fit, reducing the risk of loosening due to vibrations or external forces.

Tip: Always choose bolts with the right material and threading to match your specific application. This ensures maximum performance and safety.

Consequences of Using Incorrect Bolts

Using the wrong bolts for utility poles can lead to serious problems. Bolts that are too short or too long may compromise the structural integrity of the connection. Similarly, bolts made from low-quality materials may corrode or fail under pressure, leading to costly repairs or even safety hazards.

Improper threading can also cause issues. If the bolt does not match the nut or hardware, it may not secure the connection properly. This can result in loose fittings, which increase the risk of pole instability.

Warning: Faulty connections can lead to accidents, equipment damage, and service interruptions. Always verify that your bolts meet the required specifications.

Key Considerations for Choosing Square Head Machine Bolts

Determining the Correct Bolt Size and Length

Choosing the right bolt size and length is essential for secure utility pole connections. You need to measure the thickness of the materials being joined and account for any washers or nuts that will be used. A bolt that is too short may not fully engage the nut, while one that is too long can protrude unnecessarily, creating potential hazards.

To determine the correct size, check the diameter of the bolt. Larger diameters provide greater strength and are ideal for heavy-duty applications. Length should be calculated based on the total thickness of the materials plus the hardware.

Tip: Always keep a reference chart handy for bolt sizes and lengths to ensure accurate selection.

Selecting Durable Materials for Longevity

Material selection plays a key role in the durability of Square Head Machine Bolts. For outdoor applications like utility poles, you should prioritize corrosion-resistant materials such as galvanized steel or stainless steel. These materials withstand harsh weather conditions and resist rust, ensuring long-term performance.

Avoid bolts made from low-grade metals. They may fail under stress or degrade quickly when exposed to moisture. High-quality materials not only enhance the lifespan of the bolts but also reduce maintenance costs over time.

Note: Galvanized steel is a popular choice for utility poles due to its excellent balance of strength and corrosion resistance.

Ensuring Threading and Hardware Compatibility

Threading compatibility is critical for a secure connection. You need to match the threading of the bolt with the nut or other hardware being used. Mismatched threads can lead to loose fittings, which compromise the stability of the connection.

Examine the threading type—coarse threads are better for quick assembly, while fine threads offer greater holding power. For utility poles, coarse threads are often preferred due to their ease of use in outdoor environments.

Warning: Using incompatible threading can result in stripped threads or failed connections, which may require costly repairs.

Meeting Industry Standards for Safety

Industry standards ensure the safety and reliability of Square Head Machine Bolts in utility pole applications. You should verify that the bolts meet specifications such as ASTM or ISO standards. These standards guarantee that the bolts have been tested for strength, durability, and corrosion resistance.

Compliance with industry standards also helps you avoid liability issues. Non-compliant bolts may fail under pressure, leading to accidents or service interruptions. Always check the manufacturer’s certifications before purchasing bolts for your project.

Reminder: Look for bolts labeled with industry-standard markings to ensure they meet safety requirements.

Best Practices for Secure Utility Pole Connections

Proper Installation of Square Head Machine Bolts

Proper installation is essential for ensuring the stability and safety of utility pole connections. You need to follow a systematic approach to achieve a secure fit. Start by selecting the correct tools, such as wrenches or spanners, that match the square head design. These tools provide a firm grip, making it easier to tighten the bolts effectively.

Before installation, inspect the bolt and hardware for any signs of damage or defects. A damaged bolt can compromise the connection and lead to safety risks. Align the bolt with the pre-drilled hole on the utility pole and ensure it fits snugly. Tighten the bolt gradually, applying consistent pressure to avoid over-tightening, which can weaken the threads or damage the pole material.

Tip: Use washers to distribute the load evenly and prevent the bolt from digging into the surface. This enhances the connection's durability and reduces wear over time.

For outdoor applications, consider using anti-corrosion coatings or lubricants during installation. These measures protect the bolt from rust and ensure smooth threading. Always double-check the tightness of the bolt after installation to confirm a secure fit.

Regular Maintenance and Inspection Guidelines

Regular maintenance keeps your utility pole connections safe and functional. You should schedule routine inspections to identify potential issues before they escalate. Start by visually examining the Square Head Machine Bolts for signs of rust, wear, or loosening. Rust can weaken the bolt, while loose fittings may compromise the pole's stability.

Use a wrench to test the tightness of each bolt. If you find any loose bolts, tighten them immediately to restore the connection's integrity. For bolts exposed to harsh weather conditions, apply a fresh layer of anti-corrosion coating during maintenance. This prevents rust and extends the bolt's lifespan.

Reminder: Replace any damaged or corroded bolts promptly. Delaying replacements can lead to structural failures and safety hazards.

Create a maintenance log to track inspection dates, findings, and actions taken. This helps you stay organized and ensures that no bolts are overlooked during routine checks. For utility poles in high-traffic areas, increase the frequency of inspections to account for additional stress and vibrations.

Note: Regular maintenance not only enhances the safety of your infrastructure but also reduces long-term repair costs.

Seek Expert Advice

If you’re unsure about bolt selection, consult an expert. Professionals can guide you in choosing bolts that match your project’s mechanical and environmental demands. They can also help you interpret technical specifications and safety standards. For instance, companies like Weiye Corp have over thirty years of experience in providing high-quality fasteners and consulting services for Utility Poles. Their expertise ensures that you receive the best advice tailored to your specific needs, which can significantly reduce the risk of structural failure and ensure long-term reliability.

Prioritize Quality Over Cost

While it may be tempting to choose cheaper bolts, prioritizing quality is essential. High-quality bolts offer better strength, durability, and resistance to wear. Investing in premium bolts reduces maintenance costs and enhances the safety of your Utility Poles.

Note: Low-cost bolts may save money initially but can lead to expensive repairs later.

Choosing the right Square Head Machine Bolts strengthens your utility pole connections and ensures long-term reliability. Focus on selecting the correct size, durable materials, and compatible threading. Follow proper installation and maintenance practices to enhance safety and reduce risks. These steps help you build a secure and lasting infrastructure.

FAQ

1. How do you measure the correct bolt size for utility poles?

Measure the total thickness of materials and hardware. Choose a bolt length that fully engages the nut without protruding excessively.

2. What materials work best for outdoor utility pole bolts?

Galvanized steel or stainless steel resists corrosion and withstands harsh weather. These materials ensure durability and reduce maintenance costs over time.

3. Can mismatched threading cause connection issues?

Yes, mismatched threading leads to loose fittings or stripped threads. Always match the bolt threading with the nut or hardware for a secure connection.