How Can Blind Bolts Improve Safety and Efficiency in Steel Structure Connections?

Blind bolts have revolutionized the way Structural Steel connections are made, especially in challenging environments where access is limited. These fasteners not only meet the mechanical requirements of conventional bolts but also enable one-sided installation and tightening, making them ideal for applications like bridges, tunnels, and prefabricated buildings. The blind bolt’s design solves the issue of hard-to-reach areas, ensuring structural integrity while providing enhanced safety and efficiency.

Key Takeaways

- Blind bolts are easy to install since they need access from one side, making them great for small spaces.

- Blind bolts make structures safer by creating strong connections that stay tight over time.

- Blind bolts save time and cut labor costs, speeding up construction and making work more efficient.

What Are Blind Bolts?

Definition and Features

Blind bolts are specialized fasteners designed for steel structure connections. You can use them to secure components when access to the back side of the connection is limited or impossible.

These bolts stand out because of their versatility and durability. They perform well under heavy loads and in demanding environments. You’ll find them available in various sizes and materials, making them suitable for different applications. Their ability to adapt to tight spaces and challenging conditions makes them indispensable in modern construction projects.

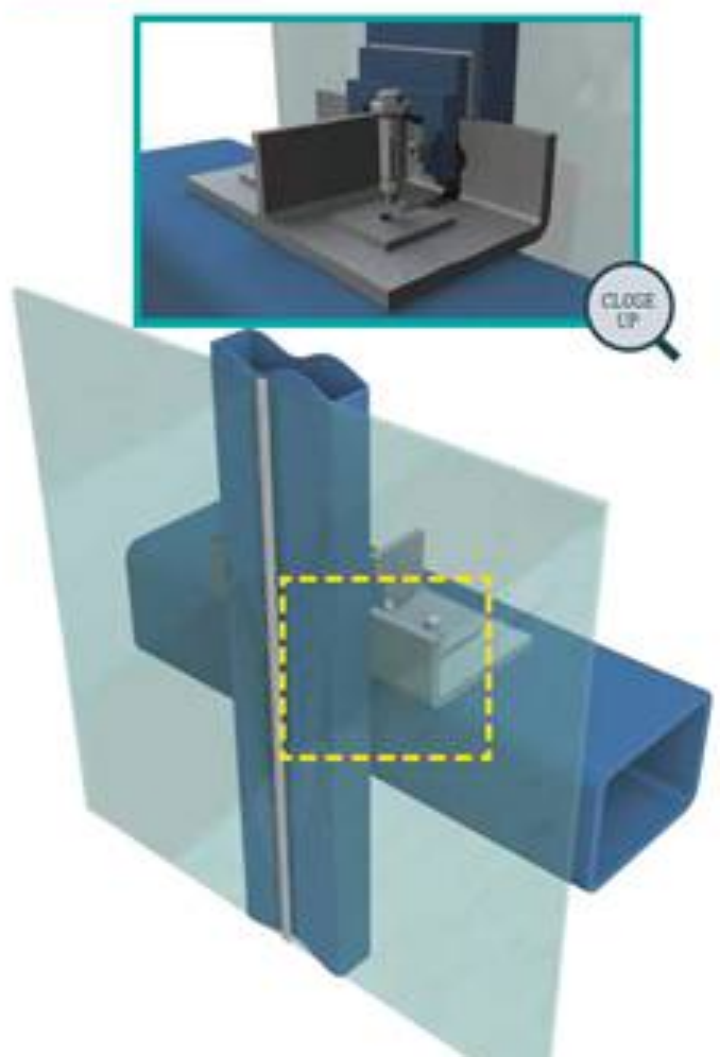

Technical Principle

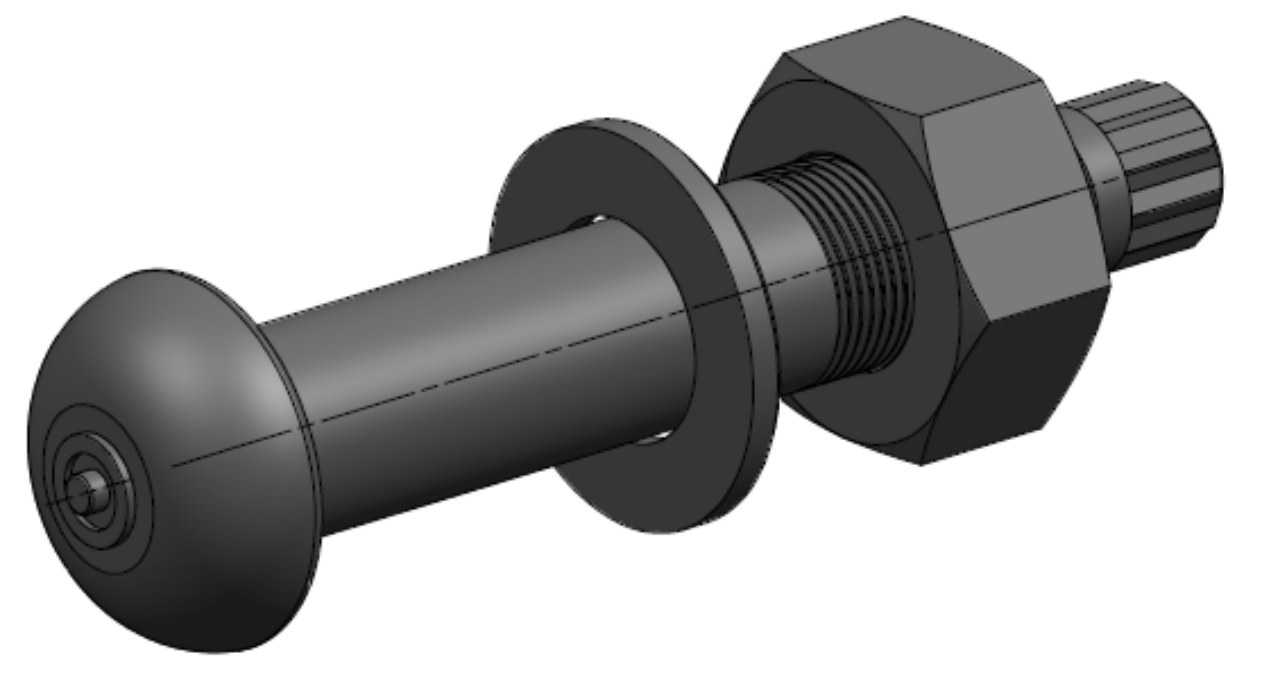

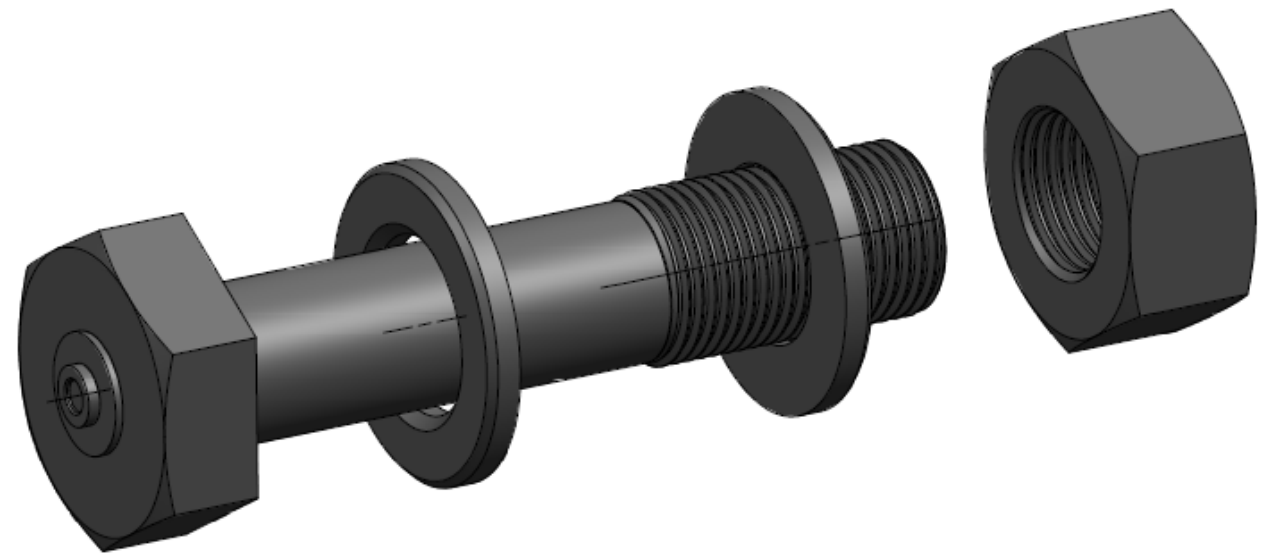

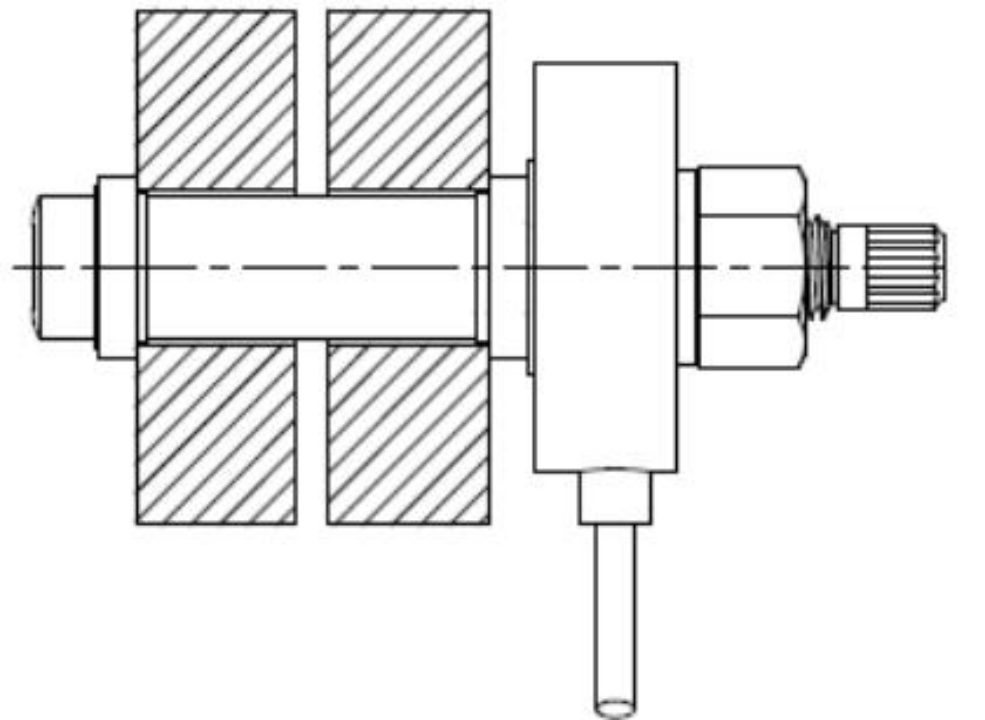

Blind bolts use a unique system that includes a fastening mechanism which expands once inserted, allowing them to secure components from just one side. This mechanism includes:

l Single-Sided Insertion: Blind bolts can be installed from one side of the structure, a crucial benefit when both sides are not accessible.

l Self-Expanding Mechanism: Upon installation, the bolt expands and locks the connection into place, providing a secure and reliable fastener.

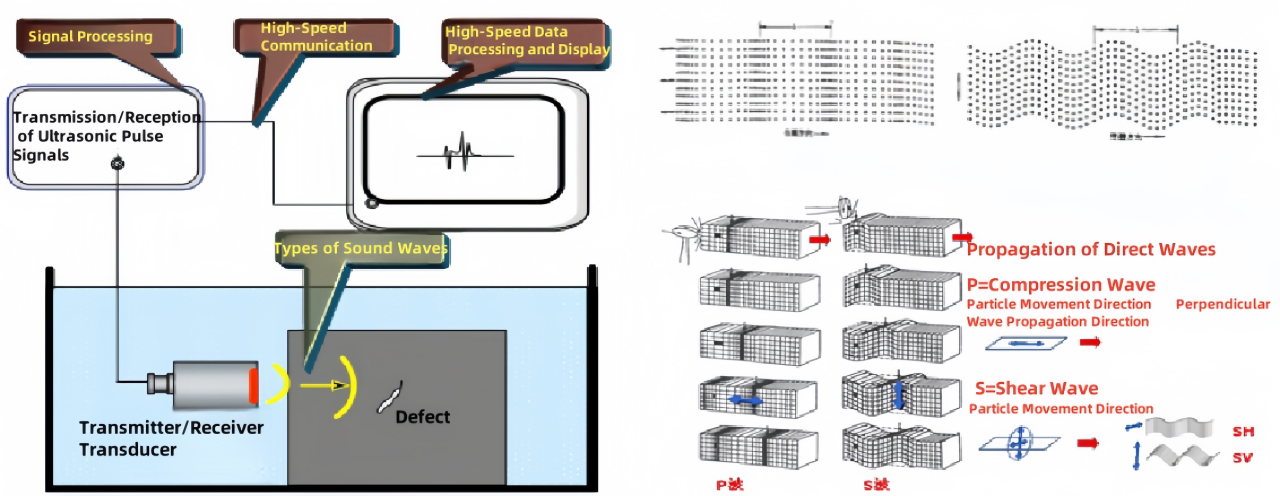

l Stress Monitoring System: Blind bolts can be equipped with sensors to monitor the stress state of the connection, allowing for real-time feedback and adjustments if necessary. This feature is especially important in high-load or high-risk applications.

Application Field

Blind bolts are highly versatile and are used across various industries and construction applications. They are particularly valuable in situations where traditional bolting methods are impractical due to limited access or space. Some key areas where blind bolts are frequently used include:

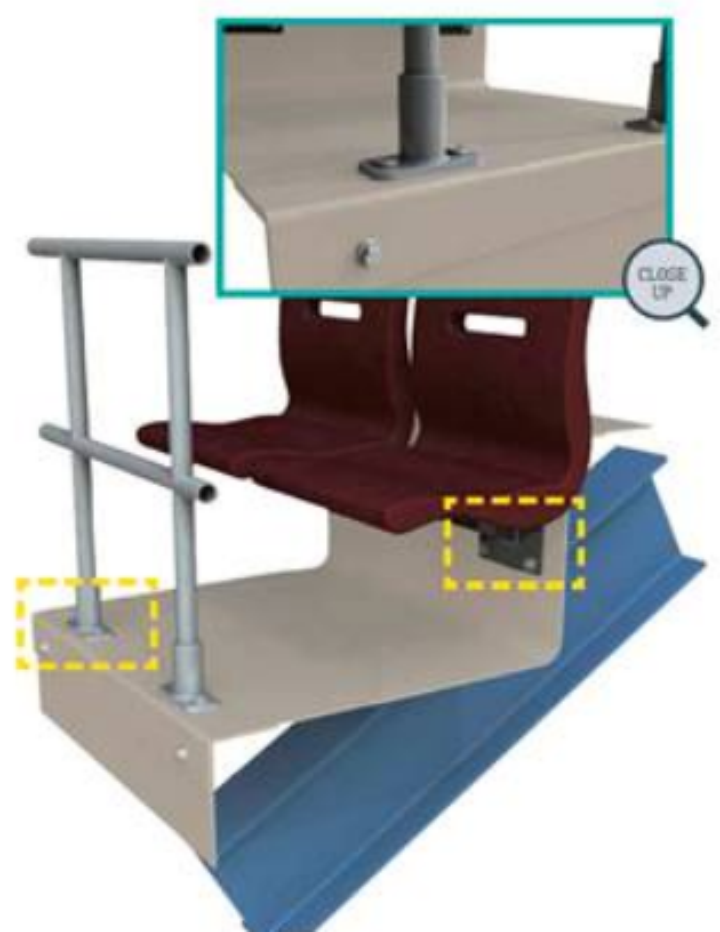

Bridge and Tunnel Construction: In bridge and tunnel construction, especially in confined spaces, blind bolts are used to secure connections where both ends of the bolts cannot be accessed. This makes installation faster and safer, as workers only need to reach one side of the structure to secure the connection.

Prefabricated Buildings: In the growing field of modular and prefabricated construction, blind bolts enable the quick and easy assembly of steel frames and other structural elements. Their ability to be installed from a single side speeds up the construction process, making them ideal for projects with tight timelines.

Steel Frame Construction: For large steel frame structures, blind bolts are an excellent solution for joining components, particularly when working with complex designs or in areas where access is restricted. These bolts are also beneficial in areas that are prone to heavy loads, ensuring long-term stability.

Wind Power Generation and Other Industrial Applications: Blind bolts are used in the installation of wind turbines and other heavy industrial equipment. Their ability to securely fasten components with limited access ensures a strong and reliable connection, even in extreme environments.

Seismic and High-Stress Areas: In areas prone to seismic activity or high mechanical stress, blind bolts help ensure that connections remain secure under dynamic loads. They are a reliable solution for infrastructure projects that require exceptional strength and safety.

How Blind Bolts Enhance Safety

Blind bolts provide multiple safety benefits, particularly in construction sites with difficult access or hazardous working conditions.

Reducing Installation Risks

Installing traditional bolts often requires access to both sides of the connection, which can be dangerous in certain situations. Blind bolts eliminate this risk by allowing you to secure connections from one side only. This feature is especially useful when working in confined spaces or at great heights, where maneuvering tools and equipment can be challenging.

The straightforward installation process of blind bolts reduces the likelihood of accidents. You don’t need to use heavy tools or complex techniques, which lowers the chances of injury during construction. Additionally, their design ensures a secure fit on the first attempt, minimizing the need for adjustments that could compromise safety.

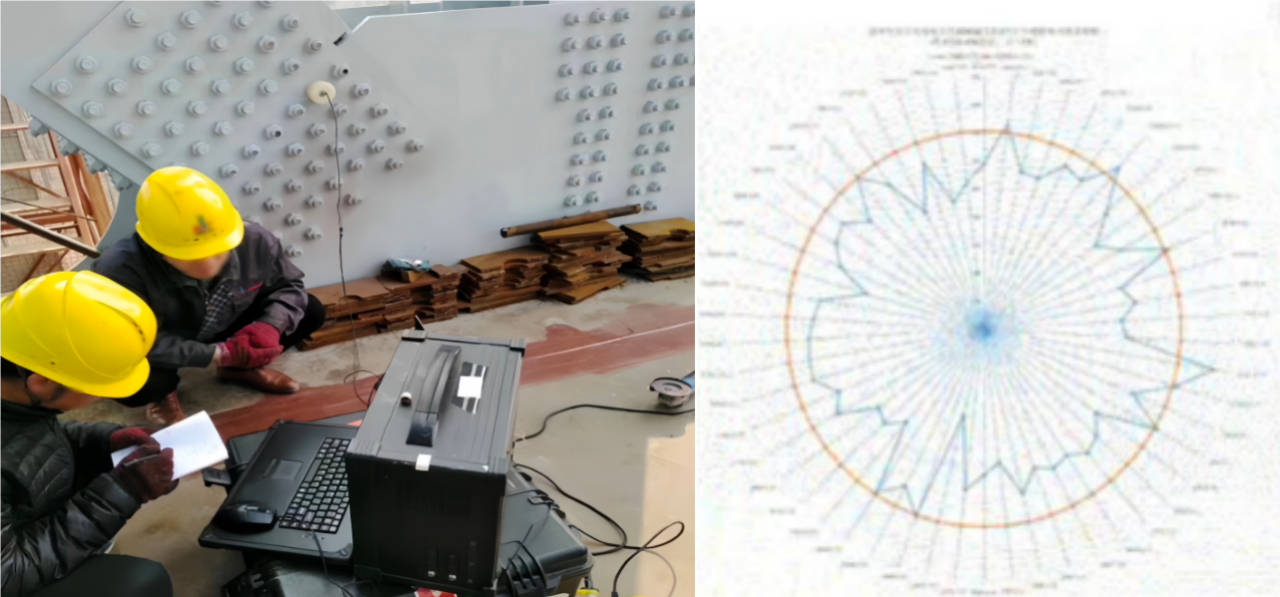

Real-Time Stress Monitoring for Ongoing Safety

Many modern blind bolts come equipped with built-in stress monitoring capabilities. This allows engineers to monitor the bolt’s stress in real time, providing an early warning in case of a malfunction. Real-time data can help identify potential weaknesses in a structure before they become critical, enabling preventative maintenance that improves long-term safety.

Reliability in Challenging Environments

Blind bolts perform exceptionally well in harsh conditions. Whether you’re dealing with extreme temperatures, high humidity, or corrosive environments, these bolts maintain their strength and durability. Their materials are often treated to resist rust and wear, ensuring long-term performance even in the toughest settings.

You’ll find blind bolts particularly useful in industries like offshore construction or mining, where environmental challenges are common. Their ability to withstand these conditions ensures that your steel structures remain safe and functional, regardless of external factors. By using blind bolts, you can trust that your connections will hold up under any circumstances.

How Blind Bolts Improve Efficiency

Simplified Installation Process

Blind bolts simplify the installation process by eliminating the need for access to both sides of a connection.

Unlike traditional bolts that require access to both sides of a steel component, blind bolts can be installed from a single side, reducing the number of workers, equipment, and time needed. This streamlines the construction process, making it particularly beneficial in large-scale projects with tight deadlines.

Time and Labor Savings

Blind bolts save you time by streamlining the installation process. Traditional bolts often require multiple steps, including aligning components and accessing both sides of the structure. With blind bolts, you can skip these steps and complete the task faster.

Labor costs also decrease when you use blind bolts. Since the installation process is simpler, fewer workers are needed to complete the job. This efficiency allows you to allocate resources to other parts of your project. Over time, these savings can significantly reduce the overall cost of construction.

Example: Imagine installing hundreds of bolts on a high-rise building. Blind bolts can cut the installation time in half, allowing your team to focus on other critical tasks.

Accessibility in Hard-to-Reach Areas

Blind bolts excel in situations where access is limited. Steel structures often include tight spaces or areas that are difficult to reach. Traditional bolts can be nearly impossible to install in these conditions. Blind bolts solve this problem by allowing you to secure connections from one side only.

You’ll find blind bolts particularly useful in projects like Bridge Construction or industrial equipment assembly. These environments often have confined spaces where traditional tools and fasteners are impractical. By using blind bolts, you can ensure a secure connection without compromising safety or efficiency.

Note: Blind bolts are designed to perform well even in the most challenging environments, making them a versatile choice for modern construction projects.

FAQ

What makes blind bolts different from traditional bolts?

Blind bolts work from one side of the connection. This feature eliminates the need for backside access, making them ideal for tight spaces or hard-to-reach areas.

Can blind bolts handle heavy loads?

Yes, blind bolts are designed for high load-bearing capacity. Their unique mechanism distributes weight evenly, ensuring secure and stable connections in demanding applications like bridges or skyscrapers.

Are blind bolts suitable for outdoor projects?

Absolutely! Blind bolts resist corrosion and withstand harsh weather conditions. You can rely on them for outdoor projects like bridges, offshore platforms, or industrial structures. 🌦️

What are the main advantages of using blind bolts?

Blind bolts simplify the installation process, especially in hard-to-reach areas, improve safety, and enhance the overall durability of steel structures.

Can blind bolts be used for both structural and non-structural applications?

Yes, blind bolts are versatile and can be used in both structural and non-structural applications, offering a reliable solution for various construction needs.

How do blind bolts improve construction efficiency?

By enabling single-sided installation, blind bolts save time and reduce labor costs, speeding up the overall construction process.

Are blind bolts suitable for use in seismic zones?

Yes, their robust design makes them an excellent choice for seismic zones, as they provide secure connections that can withstand the dynamic forces of an earthquake.

Tip: Always choose the right size and material for your specific project to maximize performance and durability.