How Can Digital Monitoring Enhance the Safety of Rock Support in Deep Mines?

Digital monitoring transforms how you approach Mining Support. These technologies provide real-time insights into rock stability, helping you detect potential hazards early. By using advanced tools, you can implement proactive safety measures, reducing risks and ensuring worker safety. With improved visibility into underground conditions, digital systems make rock support more reliable and efficient.

Key Takeaways

- Digital tools show live updates on rock strength, spotting dangers early.

- IoT sensors and smart AI systems help prevent problems and keep mines safer.

- Spending on these tools makes mining safer, cheaper, and eco-friendly over time.

Challenges of Rock Support in Deep Mines

High-Stress Environments and Rock Instability

Deep mines face extreme stress due to the weight of overlying rock layers. As you go deeper, the pressure increases, causing rock formations to become unstable. This instability can lead to sudden rock bursts or collapses, posing serious risks to mining operations.

You need to understand that high-stress environments demand robust solutions. Without proper mining support, the rock may fail under pressure, endangering workers and equipment. Advanced monitoring tools help you measure stress levels and detect early signs of instability, allowing you to take preventive action.

Tip: Regularly monitor stress levels in deep mines to identify areas prone to instability. Early detection can save lives and reduce operational downtime.

Limited Visibility and Unpredictable Geological Conditions

Underground mining presents unique challenges, especially when visibility is limited. You often work in dark, confined spaces where identifying geological features becomes difficult. Unpredictable conditions, such as hidden faults or water inflows, can compromise the stability of rock support systems.

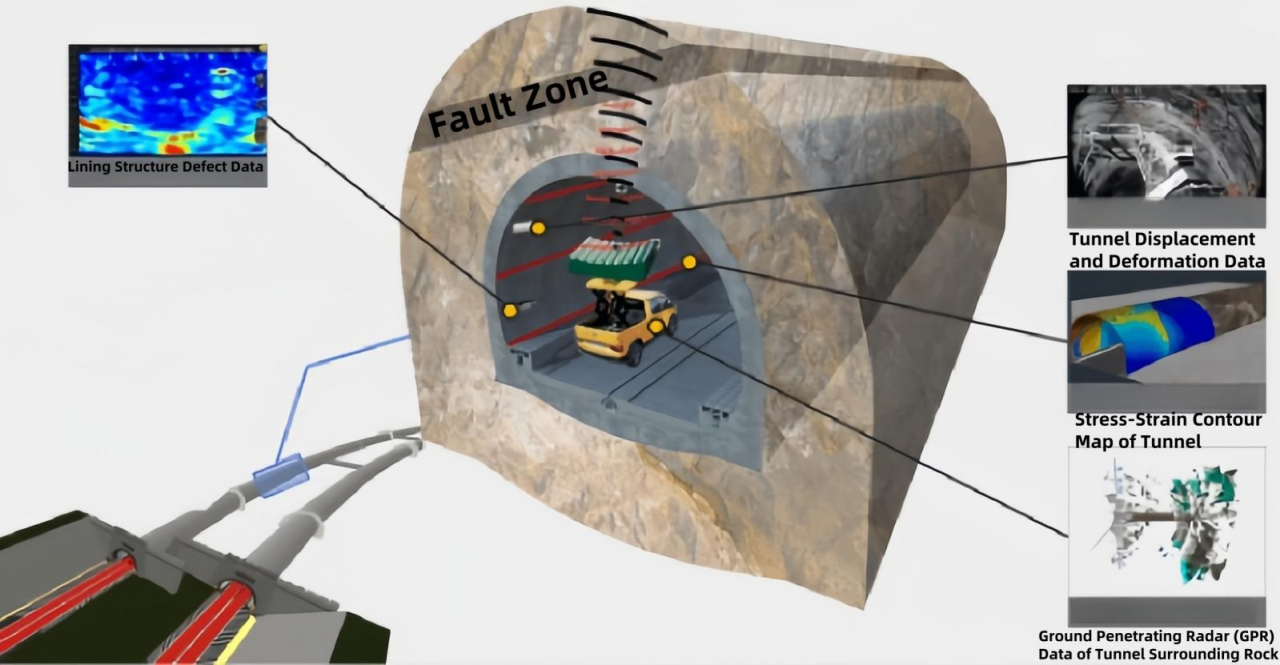

Digital monitoring technologies offer a solution. By using sensors and imaging tools, you can gain a clearer picture of the underground environment. These tools help you map geological structures and predict potential hazards, ensuring mining support remains effective even in challenging conditions.

Note: Geological unpredictability requires constant vigilance. Use digital tools to improve visibility and make informed decisions about rock support.

Risks to Worker Safety and Operational Efficiency

Worker safety is a top priority in deep mines. Rock instability and limited visibility increase the risk of accidents, which can result in injuries or fatalities. These hazards also disrupt operations, leading to costly delays and reduced efficiency.

You can mitigate these risks by adopting digital monitoring systems. These systems provide real-time data on rock stability, enabling you to respond quickly to potential threats. By improving safety measures, you protect workers and maintain operational efficiency.

Alert: Unsafe mining conditions not only endanger lives but also impact productivity. Invest in technologies that enhance safety and streamline operations.

Role of Digital Monitoring in Mining Support

Real-Time Data Collection with IoT Sensors and Intelligent Rock Bolts

Digital monitoring begins with real-time data collection. IoT sensors and intelligent Rock Bolts play a critical role in gathering accurate information about underground conditions. These devices measure stress, pressure, and movement within the rock formations. You can use this data to monitor changes in rock stability as they happen.

IoT sensors are small but powerful. They continuously send data to a central system, allowing you to track conditions without manual inspections. Intelligent rock bolts, on the other hand, combine structural support with monitoring capabilities. They detect shifts in the rock and alert you to potential hazards.

Tip: Install IoT sensors and intelligent rock bolts in high-risk areas. This ensures you receive timely updates and can act quickly to prevent accidents.

Predictive Analytics and AI for Early Warning Systems

Predictive Analytics and AI take digital monitoring to the next level. These technologies analyze the data collected by sensors to identify patterns and trends. By doing so, they help you predict potential rock failures before they occur.

AI-powered systems process vast amounts of information in seconds. They provide early warning alerts, giving you enough time to reinforce mining support or evacuate workers if necessary. Predictive analytics also helps you optimize resource allocation by focusing on areas that need immediate attention.

Alert: Early warning systems powered by AI can save lives and reduce downtime. Use them to stay ahead of potential risks.

3D Modeling, Digital Twins, and Simulation for Rock Support Design

3D modeling and digital twins revolutionize how you design and evaluate mining support systems. A digital twin is a virtual replica of your mine. It allows you to simulate various scenarios and test the effectiveness of rock support designs.

With 3D modeling, you can visualize the underground environment in detail. This helps you identify weak points and plan reinforcements more effectively. Simulations enable you to predict how the rock will behave under different conditions, ensuring your support systems are robust and reliable.

Note: Use digital twins and simulations to refine your mining support strategies. This reduces trial-and-error and improves safety outcomes.

Real-World Applications of Digital Monitoring in Deep Mines

Case Study: IoT Sensors Enhancing Safety in South Deep Gold Mine

The South Deep Gold Mine in South Africa demonstrates how IoT sensors improve safety. You can find these sensors embedded in rock formations, where they monitor stress and movement. They send real-time data to a central system, helping you detect early signs of instability. This proactive approach has reduced accidents and improved worker safety.

In this mine, IoT sensors also track environmental factors like temperature and humidity. These insights allow you to maintain optimal conditions underground. By using this technology, the South Deep Gold Mine has set a benchmark for safety in deep mining operations.

Example: AI-Driven Monitoring Systems Preventing Rock Failures in Australian Mines

Australian mines have adopted AI-driven monitoring systems to prevent rock failures. These systems analyze data from sensors and predict potential hazards. You can rely on AI to provide early warnings, giving you time to reinforce weak areas.

One example is the use of AI in coal mines, where it identifies patterns in seismic activity. This helps you understand when and where rock failures might occur. By integrating AI into your operations, you can enhance safety and reduce downtime.

Broader Benefits of Digital Monitoring in Mining Support

Enhanced Worker Safety and Reduced Accidents

Digital monitoring significantly improves worker safety in deep mines. By providing real-time data on rock stability, these systems help you identify hazards before they escalate. Early warnings allow you to take immediate action, such as reinforcing weak areas or evacuating workers. This proactive approach reduces the likelihood of accidents and ensures a safer working environment.

You can also rely on technologies like IoT sensors and seismic monitoring to track underground conditions continuously. These tools minimize the need for manual inspections in dangerous areas, further protecting workers.

Tip: Regularly review safety data from digital monitoring systems to stay ahead of potential risks.

Increased Operational Efficiency and Cost Savings

Digital monitoring enhances operational efficiency by streamlining processes and reducing downtime. Real-time insights help you allocate resources more effectively, focusing on areas that need immediate attention. Predictive analytics also allows you to plan maintenance and repairs in advance, avoiding costly disruptions.

By preventing accidents and equipment failures, you save money on repairs and compensation. Additionally, technologies like 3D modeling and digital twins optimize the design of mining support systems, reducing material waste and improving overall efficiency.

Note: Investing in digital monitoring not only boosts safety but also delivers long-term cost savings.

Positive Impact on Community and Environmental Safety

The benefits of digital monitoring extend beyond the mine. By preventing rock failures and minimizing environmental damage, you contribute to the safety of nearby communities. Technologies like ground-penetrating radar help you identify and mitigate risks, such as water inflows or subsidence, that could impact surrounding areas.

Digital tools also promote sustainable mining practices. By optimizing resource use and reducing waste, you minimize the environmental footprint of your operations. This fosters trust and goodwill among local communities.

Alert: Safe and sustainable mining practices benefit both your operations and the environment.

Digital monitoring transforms mining safety in deep mines. It helps you address challenges like rock instability and limited visibility. By adopting these tools, you improve worker safety and operational efficiency.

Tip: Stay ahead by embracing innovations like IoT sensors and AI. These technologies ensure reliable rock support and a safer mining future.

FAQ

What is digital monitoring in mining support?

Digital monitoring uses advanced tools like sensors and AI to track rock stability. It helps you detect hazards early and improve safety in deep mines.

How does predictive analytics enhance mining support?

Predictive analytics analyzes data to forecast rock failures. It allows you to take preventive measures, ensuring safer and more efficient mining operations.

Can digital monitoring reduce mining costs?

Yes, digital monitoring optimizes resource use and prevents accidents. It saves money on repairs and improves the efficiency of mining support systems.