How Does an Inverted Cone Chemical Anchor Bolt Enhance Structural Stability in Building Connections?

You rely on strong building connections to ensure safety and durability. The inverted cone chemical anchor bolt achieves this by distributing loads evenly and forming a powerful bond with materials like concrete. Its design resists environmental stress, making it a reliable choice for modern construction projects where stability is critical.

Key Takeaways

- The upside-down cone anchor bolt spreads weight evenly. This lowers pressure on nearby materials and makes structures stronger.

- Its chemical bond sticks firmly to concrete, creating a tough hold. This makes it great for heavy-duty uses like bridges or factories.

- This bolt can handle harsh weather, lasting a long time. It also cuts down on repair costs in tough building areas.

Understanding the Inverted Cone Chemical Anchor Bolt

What Is an Inverted Cone Chemical Anchor Bolt?

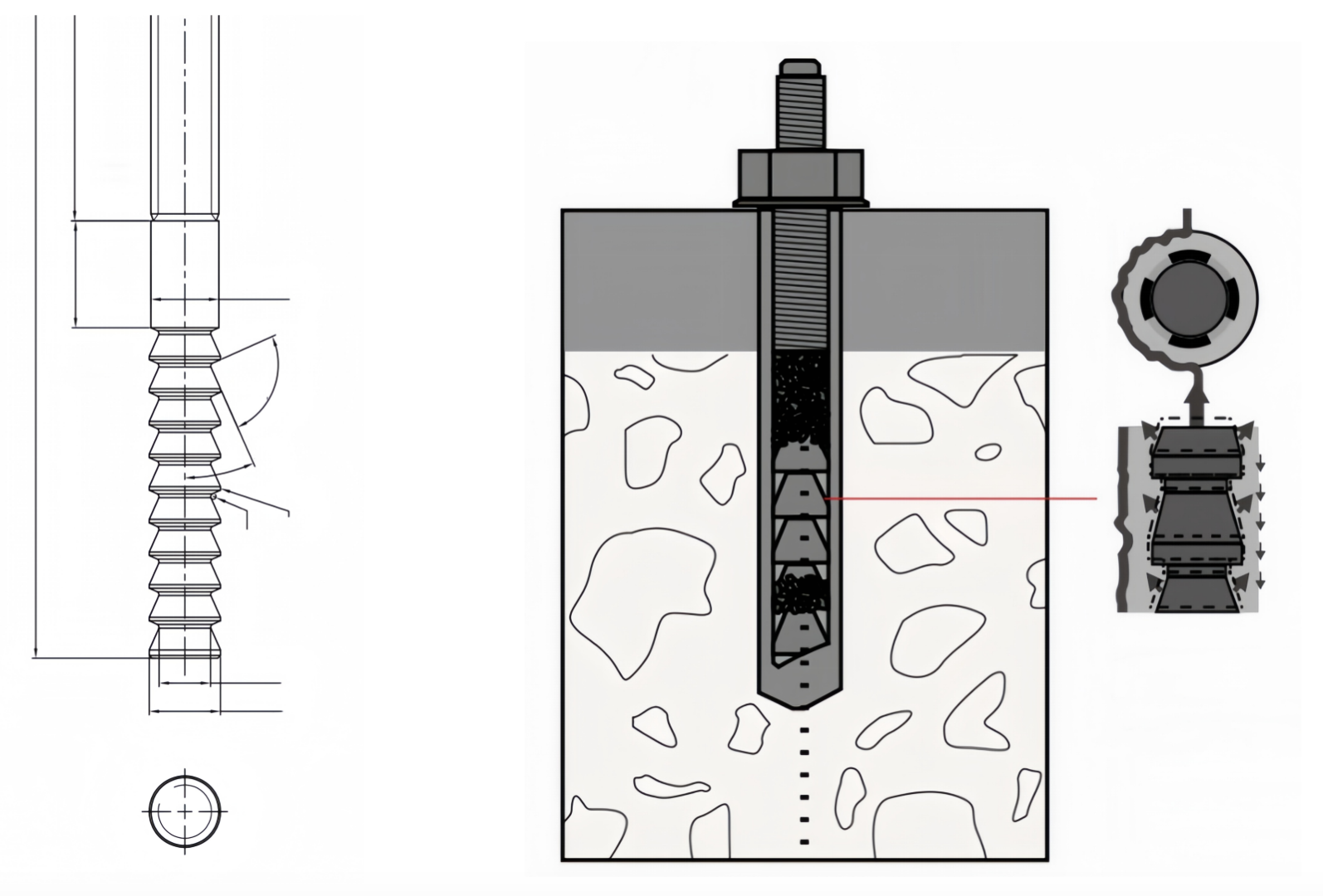

You may wonder what makes the inverted cone chemical anchor bolt unique. This specialized fastener combines mechanical design with chemical bonding to create a secure connection in construction projects. Its inverted cone shape allows it to distribute forces evenly, reducing stress on the surrounding material.

Unlike traditional bolts, this anchor bolt uses a chemical adhesive to bond with concrete or other building materials. The adhesive fills gaps and creates a strong, durable connection that resists movement and wear over time. This innovative approach makes it ideal for applications requiring high stability and reliability.

Tip: If you're working on a project that demands superior load-bearing capacity, the inverted cone chemical anchor bolt is a solution worth considering.

Key Features of the Inverted Cone Design

The inverted cone design offers several features that enhance its performance:

- Optimized Load Distribution: The cone shape spreads forces across a wider area, preventing localized stress points.

- Chemical Bonding: The adhesive used with the bolt creates a seamless connection with concrete, ensuring long-term stability.

- Resistance to Pull-Out Forces: The inverted cone shape locks the bolt securely in place, even under heavy loads.

These features make the inverted cone chemical anchor bolt a reliable choice for demanding construction environments.

Differences Between Inverted Cone and Traditional Anchor Bolts

When comparing inverted cone chemical Anchor Bolts to traditional anchor bolts, you’ll notice key differences:

| Feature | Inverted Cone Chemical Anchor Bolt | Traditional Anchor Bolt |

|---|---|---|

| Bonding Mechanism | Chemical adhesive | Mechanical fastening |

| Load Distribution | Evenly spread | Concentrated at specific points |

| Resistance to Environmental Stress | High | Moderate |

| Durability | Long-term | May require frequent maintenance |

Traditional anchor bolts rely on mechanical force to hold materials together, which can lead to uneven stress distribution. In contrast, the inverted cone chemical anchor bolt combines its unique shape with chemical bonding to deliver superior performance.

How the Inverted Cone Chemical Anchor Bolt Works

The Role of the Inverted Cone Shape in Load Distribution

The inverted cone shape plays a critical role in how this anchor bolt distributes loads. When you install the bolt, its unique geometry ensures that forces are spread evenly across a larger surface area. This reduces the risk of stress concentrating in one spot, which could weaken the surrounding material.

Imagine pressing a cone into soft clay. The wider base of the cone spreads the pressure outward, preventing the clay from cracking under the force. Similarly, the inverted cone chemical anchor bolt uses its shape to minimize localized stress, making it ideal for applications where stability is essential.

This design also enhances the bolt's ability to resist pull-out forces. As the load increases, the cone shape locks the bolt more securely into place, ensuring a firm connection even under heavy stress.

Note: By reducing stress concentrations, the inverted cone shape helps extend the lifespan of both the bolt and the material it anchors.

Chemical Bonding Mechanism and Adhesive Properties

The chemical bonding mechanism is another key feature of the inverted cone chemical anchor bolt. When you apply the adhesive, it fills the gaps between the bolt and the surrounding material, creating a seamless bond. This chemical interaction strengthens the connection and prevents movement over time.

The adhesive used with these bolts is specially formulated to resist environmental factors like moisture, temperature changes, and chemical exposure. This ensures that the bond remains strong even in challenging conditions.

Unlike mechanical fasteners, which rely solely on friction or pressure, the chemical adhesive forms a molecular-level connection with the material. This not only enhances the bolt's load-bearing capacity but also reduces the likelihood of failure due to wear or corrosion.

Tip: Always choose an adhesive compatible with the materials in your project to maximize the performance of the inverted cone chemical anchor bolt.

Interaction with Concrete and Other Building Materials

The inverted cone chemical anchor bolt is designed to work seamlessly with materials like concrete, brick, and stone. When you install the bolt in concrete, the adhesive penetrates the tiny pores in the material, creating a bond that is both mechanical and chemical. This dual interaction ensures a secure and durable connection.

For other materials, such as masonry or natural stone, the bolt adapts to the unique properties of the substrate. The inverted cone shape provides mechanical stability, while the adhesive compensates for any irregularities in the material's surface.

This adaptability makes the bolt a versatile choice for various construction applications. Whether you're working on a high-rise building or an industrial facility, the inverted cone chemical anchor bolt offers reliable performance across different materials.

Reminder: Proper surface preparation is crucial for achieving the best results. Clean the material thoroughly before applying the adhesive to ensure a strong bond.

Structural Stability Benefits of the Inverted Cone Chemical Anchor Bolt

Enhanced Load-Bearing Capacity

You need a solution that can handle heavy loads without compromising safety. The inverted cone chemical anchor bolt excels in this area. Its unique shape spreads forces evenly across the material, reducing stress points. This design prevents cracks and ensures the bolt stays firmly in place, even under extreme pressure.

The chemical adhesive further boosts load-bearing capacity. It creates a seamless bond with concrete or other materials, eliminating weak spots. This combination of mechanical and chemical strength makes the bolt ideal for projects requiring high stability, such as bridges or industrial facilities.

Tip: For projects with heavy loads, the inverted cone chemical anchor bolt offers unmatched reliability.

Resistance to Environmental Stressors

Environmental factors like moisture, temperature changes, and chemical exposure can weaken traditional fasteners. You won’t face this issue with the inverted cone chemical anchor bolt. Its adhesive resists water and temperature fluctuations, maintaining a strong bond in challenging conditions.

The inverted cone design also enhances resistance to pull-out forces caused by vibrations or shifting loads. This makes the bolt suitable for areas prone to earthquakes or heavy machinery.

Reminder: Choose this bolt for environments where durability against weather and stress is essential. 🌦️

Long-Term Durability and Reduced Maintenance

Durability matters when you want to minimize maintenance costs. The inverted cone chemical anchor bolt offers long-term performance. Its chemical bond prevents wear and corrosion, reducing the need for frequent inspections or replacements.

The inverted cone shape locks the bolt securely, ensuring it remains effective for years. This reliability saves you time and money, making it a cost-effective choice for modern construction projects.

Note: Investing in durable solutions like this bolt reduces long-term maintenance expenses.

Applications of Inverted Cone Chemical Anchor Bolts in Construction

High-Stress Structural Connections

You often face challenges when working on projects that require secure connections under heavy loads. The inverted cone chemical anchor bolt provides a solution for these high-stress scenarios. Its unique design distributes forces evenly, reducing the risk of material failure. This makes it ideal for applications like anchoring machinery, supporting beams, or stabilizing walls in industrial settings.

The chemical bonding mechanism ensures the bolt stays firmly in place, even when subjected to vibrations or shifting loads. This reliability allows you to focus on other aspects of your project without worrying about structural integrity.

Tip: Use this bolt for areas where stability under extreme pressure is critical.

Use in Bridges, High-Rises, and Industrial Facilities

Modern construction projects demand materials that can withstand harsh conditions. You’ll find the inverted cone chemical anchor bolt particularly useful in bridges, high-rise buildings, and industrial facilities. Its ability to resist environmental stressors like moisture and temperature changes makes it a dependable choice for outdoor structures.

In bridges, the bolt secures components exposed to constant vibrations and heavy traffic. In high-rises, it anchors structural elements that bear immense loads. Industrial facilities benefit from its durability in environments with chemical exposure or heavy machinery.

Reminder: Choose this bolt for projects requiring long-term performance in demanding environments.

Meeting Modern Construction Standards

Construction standards today emphasize safety, durability, and efficiency. The inverted cone chemical anchor bolt meets these requirements by combining innovative design with advanced materials. Its chemical bonding mechanism ensures compliance with load-bearing and environmental resistance standards.

You can rely on this bolt to meet the demands of modern engineering practices. Whether you’re working on a large-scale infrastructure project or a smaller commercial building, it provides the stability needed to adhere to strict regulations.

Note: Using this bolt helps you achieve higher safety ratings and reduces the risk of structural failure.

You gain significant advantages by using the inverted cone chemical anchor bolt in construction. Its innovative design enhances load distribution and bonding strength. This bolt resists environmental stress and ensures durable connections. These features make it a reliable solution for modern building projects where structural stability is essential.

FAQ

What makes the inverted cone chemical anchor bolt better than traditional bolts?

Its unique shape and chemical bonding mechanism provide superior load distribution, enhanced durability, and resistance to environmental stress, making it more reliable for demanding construction projects.

How do you ensure proper installation of these anchor bolts?

Clean the surface thoroughly, apply the adhesive evenly, and follow the manufacturer’s instructions to achieve a secure and durable connection with the material.