How Liner Bolts Contribute to Equipment Durability?

Liner Bolts play a crucial role in protecting your machinery. These bolts secure liners, which shield equipment from wear caused by constant use. This protective system reduces damage and keeps your machines running longer. By using a high-quality liner bolt, you can minimize costly repairs and ensure your equipment performs reliably over time.

Key Takeaways

- Liner bolts hold liners in place. This lowers machine damage and makes equipment last longer.

- Good-quality liner bolts need less fixing and save time. They help machines run better and boost work output.

- Checking liner bolts often is very important. It finds problems early and keeps machines safe and reliable.

Understanding Liner Bolts

What Are Liner Bolts

A liner bolt is a specialized fastener designed to secure liners in industrial equipment. These bolts hold the protective liners in place, ensuring they remain stable during operation. Liners act as a shield, protecting machinery from damage caused by friction, impact, or abrasion. Without these bolts, liners could shift or loosen, leading to equipment failure.

You’ll often find liner bolts in heavy-duty machinery used in industries like mining, cement production, and power generation. Their design allows them to withstand extreme conditions, such as high temperatures and constant vibrations. This durability makes them a critical component in maintaining the efficiency and safety of industrial equipment.

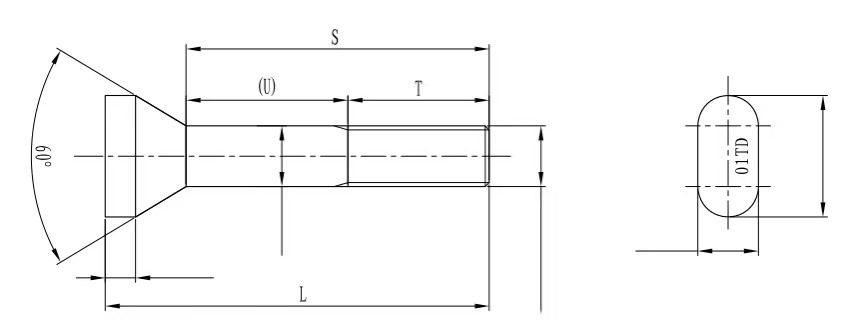

Purpose and Features of Liner Bolts

The primary purpose of a liner bolt is to keep liners securely attached to the machinery. This prevents wear and tear on the equipment’s main structure. By doing so, these bolts help extend the lifespan of your machinery and reduce the need for frequent repairs.

Liner bolts come with unique features that enhance their performance. Many are made from high-strength materials like alloy steel, which resists corrosion and deformation. Some designs include a locking mechanism to prevent loosening during operation. These features ensure that the bolts remain reliable even under intense working conditions.

Tip: Regularly inspecting and maintaining your liner bolts can further improve your equipment’s durability and performance.

Industrial Applications of Liner Bolts

Mining Equipment

Cement Production Machinery

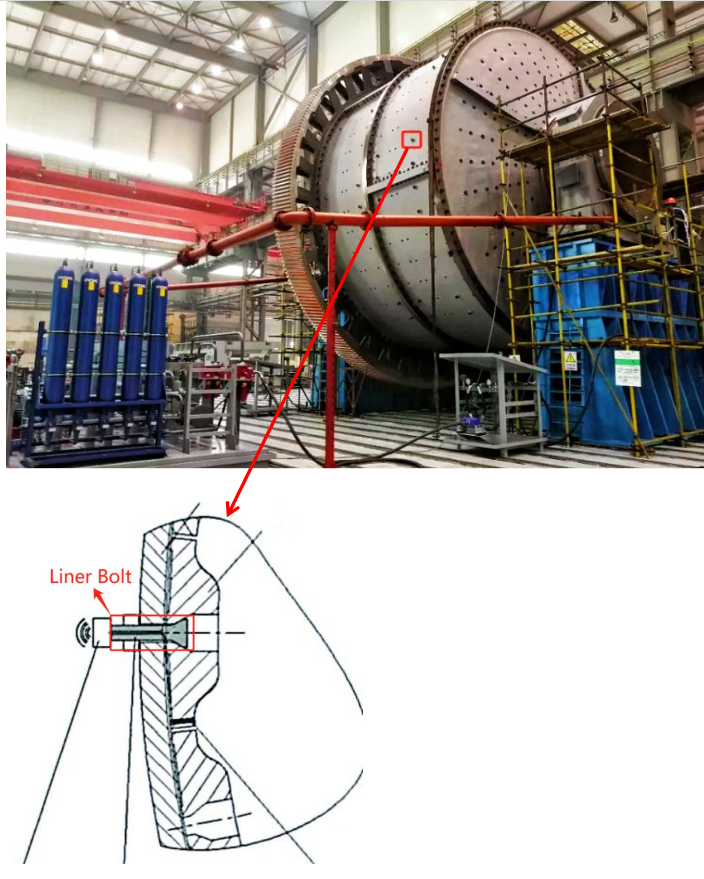

Cement production involves grinding raw materials into fine powder, which puts significant stress on machinery. Liner bolts are essential for holding liners in place within ball mills and rotary kilns. These liners shield the equipment from the abrasive action of cement particles. When you use high-quality liner bolts, you minimize the risk of equipment failure and maintain consistent production levels.

Power Generation Systems

Power plants rely on heavy-duty equipment like turbines and boilers to generate electricity. These machines operate under high temperatures and pressures, making them prone to wear. Liner bolts secure protective liners that safeguard critical components from damage. This not only enhances the durability of the equipment but also ensures uninterrupted power generation.

Heavy Machinery and Manufacturing

In manufacturing industries, heavy machinery often handles repetitive tasks under intense conditions. Liner bolts help secure liners that protect machine surfaces from friction and impact. Whether it’s a press, conveyor, or molding machine, using durable liner bolts can improve efficiency and reduce maintenance needs. This keeps your operations running smoothly and safely.

Enhancing Equipment Durability with Liner Bolts

Reducing Wear and Tear

Liner bolts play a vital role in reducing wear and tear on industrial equipment. By securing liners in place, they prevent direct contact between machinery components and abrasive materials. This protective barrier minimizes surface damage and extends the lifespan of your equipment. For example, in mining operations, a properly installed liner bolt ensures that liners remain stable, even under heavy loads. This stability reduces the risk of costly repairs caused by excessive wear.

Improving Efficiency

When equipment operates efficiently, productivity increases. Liner bolts contribute to this by maintaining the integrity of liners, which optimize the performance of machinery. A secure liner reduces energy loss caused by friction or misalignment. In cement production, for instance, a well-fastened liner bolt ensures smooth grinding processes, leading to consistent output. This efficiency not only saves energy but also enhances overall operational performance.

Minimizing Maintenance Downtime

Frequent maintenance disrupts operations and increases costs. Liner bolts help minimize downtime by keeping liners securely in place, reducing the need for constant adjustments or replacements. High-quality liner bolts, made from durable materials, resist loosening even in harsh conditions. This reliability allows you to focus on production rather than repairs, ensuring uninterrupted workflow.

Ensuring Safety and Reliability

Safety is a top priority in any industrial setting. A loose liner can lead to equipment failure, posing risks to workers and machinery. Liner bolts enhance safety by preventing such failures. Their robust design ensures that liners stay firmly attached, even during intense operations. This reliability gives you peace of mind, knowing your equipment operates safely and consistently.

Liner bolts play a critical role in keeping your industrial equipment durable and efficient. They reduce wear, improve performance, and lower maintenance needs. Choosing high-quality liner bolts ensures your machinery operates reliably and lasts longer. By investing in the right components, you protect your equipment and maintain smooth operations across industries.

FAQ

What materials are used to make liner bolts?

Liner bolts are typically made from high-strength materialslike alloy steel or Stainless Steel. These materials resist corrosion, deformation, and wear, ensuring durability in harsh industrial environments.

How often should you inspect liner bolts?

Inspect liner bolts regularly, ideally during routine maintenance. Frequent checks help you identify wear, loosening, or damage early, preventing equipment failure and ensuring safe operations.

Tip: Create a maintenance schedule to track inspections and replacements for optimal performance.

Can you reuse liner bolts after removal?

Reusing liner bolts is not recommended. Removal can weaken their structural integrity, increasing the risk of failure. Always replace them with new, high-quality bolts for maximum safety and reliability.

⚠️ Note: Using worn bolts may compromise equipment durability and worker safety.