Marine Construction Timber Bolts: Essential Fasteners for Durable Dock Building

Building a dock that withstands harsh marine conditions requires the right materials. Timber Bolts play a vital role in ensuring your dock stays strong and secure. These fasteners resist environmental wear and provide unmatched durability. Whether battling salty air or constant moisture, they help your dock remain stable and reliable for years.

Key Takeaways

· Timber bolts are important for building docks. They make docks strong and steady, helping them survive tough water conditions.

· Pick the right material for your timber bolts. Galvanized steel works well in freshwater, while Stainless Steel is better for salty water.

· Taking care of bolts is very important. Check for rust or damage often, and replace bad bolts to keep your dock safe and working.

What Are Timber Bolts and Their Role in Dock Construction?

Definition of Timber Bolts

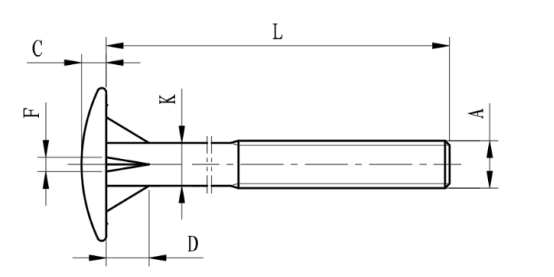

A timber bolt is a specialized fastener designed to secure wooden components in construction projects. Unlike standard bolts, timber bolts feature a large, rounded head that provides a broader surface area for better grip and stability. This unique design ensures that the bolt stays firmly in place, even under heavy loads or shifting conditions. You’ll often find timber bolts used in projects where strength and durability are critical, such as docks, piers, and other marine structures.

Timber bolts are typically made from corrosion-resistant materials like galvanized steel or stainless steel. These materials help the bolts withstand exposure to moisture, salt, and other harsh elements commonly found in marine environments. Their ability to resist rust and degradation makes them an essential component for long-lasting dock construction.

Importance in Marine Construction

In marine construction, timber bolts play a crucial role in maintaining the structural integrity of your dock. The constant exposure to water, wind, and salt can weaken traditional fasteners over time. Timber bolts, however, are specifically designed to endure these challenges. By using these bolts, you ensure that your dock remains stable and secure, even in the face of harsh weather conditions.

Another key advantage of timber bolts is their ability to distribute pressure evenly across wooden surfaces. This reduces the risk of splitting or cracking, which can compromise the safety and longevity of your dock. Whether you’re anchoring beams, securing planks, or reinforcing joints, timber bolts provide the strength and reliability needed for marine construction.

Tip: Always choose timber bolts that match the specific requirements of your project. The right size and material can make a significant difference in the performance and durability of your dock.

Benefits of Using Timber Bolts in Marine Construction

Durability in Marine Environments

Marine environments are harsh. Constant exposure to water, wind, and salt can weaken many materials. Timber bolts, however, are built to last. These fasteners are designed to handle the unique challenges of marine construction. They hold wooden components together firmly, even when the dock faces strong waves or heavy loads.

You can rely on timber bolts to maintain their strength over time. Their robust design ensures that your dock remains stable, even in extreme weather. This durability makes them a smart choice for anyone building a dock in a marine setting.

Corrosion Resistance for Longevity

Corrosion is one of the biggest threats to any structure near water. Salt in the air and water speeds up rusting, which can weaken fasteners. Timber bolts solve this problem. Made from materials like galvanized steel or stainless steel, they resist corrosion effectively.

When you use timber bolts, you protect your dock from rust-related damage. This resistance to corrosion extends the life of your dock. It also reduces the need for frequent repairs or replacements, saving you time and money in the long run.

Note: Always choose timber bolts with the right coating or finish for marine applications. This extra layer of protection enhances their ability to resist corrosion.

Structural Integrity and Safety

A dock must be safe and secure. Timber bolts play a key role in ensuring this. They provide a strong connection between wooden components, preventing movement or loosening over time. This stability is crucial for the safety of anyone using the dock.

Timber bolts also help distribute weight evenly across the structure. This reduces the risk of wood splitting or cracking under pressure. By using these fasteners, you create a dock that not only lasts but also keeps everyone safe.

Tip: Inspect your timber bolts regularly to ensure they remain in good condition. Tighten or replace them as needed to maintain the structural integrity of your dock.

Choosing the Right Timber Bolts for Your Dock

Material Selection: Galvanized vs. Stainless Steel

Choosing the right material for your bolts is critical for dock durability. Galvanized steel bolts are coated with a layer of zinc, which protects them from rust. These bolts are cost-effective and work well in freshwater environments. However, they may not last as long in saltwater conditions.

Stainless steel bolts, on the other hand, offer superior corrosion resistance. They are ideal for saltwater docks because they withstand the harsh effects of salt and moisture. While stainless steel bolts are more expensive, their long-term durability often makes them a better investment for marine construction.

Tip: Consider the environment where your dock will be built. For saltwater areas, stainless steel is usually the best choice.

Proper Sizing for Structural Needs

The size of your bolts directly impacts the strength of your dock. Larger bolts provide more holding power, making them suitable for heavy-duty applications. Smaller bolts work well for lighter structures but may not handle significant loads.

Measure the thickness of the wood and the load requirements of your dock before selecting bolt sizes. Using bolts that are too small can compromise the stability of your structure. On the other hand, oversized bolts may damage the wood or create unnecessary costs.

Note: Always consult a professional or refer to construction guidelines to determine the correct bolt size for your project.

Coatings and Finishes for Marine Applications

Coatings and finishes add an extra layer of protection to your bolts. Hot-dip galvanizing is a popular option for galvanized bolts, as it provides a thick, durable coating. Stainless steel bolts often come with polished finishes that enhance their resistance to corrosion.

For docks in highly corrosive environments, consider bolts with specialized marine-grade coatings. These finishes are designed to withstand extreme conditions, ensuring your dock remains secure and long-lasting.

Tip: Check the manufacturer’s specifications to ensure the coating or finish is suitable for marine use.

Installation and Maintenance Tips for Timber Bolts

Best Practices for Installation

Installing timber bolts correctly ensures your dock’s stability and longevity. Start by drilling precise pilot holes in the wood. These holes prevent splitting and make it easier to insert the bolts. Use a wrench or socket tool to tighten the bolts securely. Avoid over-tightening, as this can damage the wood or strip the threads.

When working in a marine environment, always use bolts with corrosion-resistant coatings. This protects them from rust and ensures a longer lifespan. For added security, consider using washers. They distribute pressure evenly and reduce the risk of the bolt loosening over time.

Tip: Double-check the alignment of your wooden components before tightening the bolts. Proper alignment ensures a stronger and more stable structure.

Routine Maintenance for Longevity

Regular maintenance keeps your dock safe and functional. Inspect the bolts periodically for signs of rust, wear, or loosening. Tighten any bolts that have become loose. Replace damaged or corroded bolts immediately to prevent further structural issues.

Clean the bolts and surrounding wood to remove salt and debris. This simple step reduces the risk of corrosion and extends the life of your dock. For docks in saltwater environments, consider applying a protective coating to the bolts annually.

Note: Keep a maintenance schedule to ensure you don’t miss inspections or necessary repairs.

Avoiding Common Installation Mistakes

Avoiding mistakes during installation saves time and money. One common error is using bolts that are too short or too long. Short bolts may not provide enough grip, while long bolts can damage the wood. Always measure carefully before selecting bolt sizes.

Another mistake is skipping the pilot holes. Without them, the wood may crack or split during installation. Also, avoid using bolts without corrosion-resistant coatings in marine environments. This oversight can lead to rust and weaken your dock over time.

Tip: Follow manufacturer guidelines for bolt installation to ensure the best results.

Timber bolts are vital for building docks that last in marine environments. Choosing the right timber bolt ensures your dock stays strong and safe. Proper installation and regular maintenance protect your investment and extend its lifespan. By prioritizing high-quality fasteners, you create a dock that withstands harsh conditions and serves you for years.

FAQ

What makes timber bolts different from regular bolts?

Timber bolts have a large, rounded head for better grip and stability. They are also made from corrosion-resistant materials, making them ideal for marine environments.

How do I know which size timber bolt to use?

Measure the wood's thickness and the dock's load requirements. Larger bolts provide more strength, while smaller bolts suit lighter structures. Always consult construction guidelines for accuracy.

Tip: Use a professional's advice to ensure the correct bolt size for your project.

Can I reuse timber bolts during dock repairs?

Reusing timber bolts is not recommended. Corrosion or wear may weaken them over time. Always replace old bolts with new, corrosion-resistant ones for safety and durability.