0102030405

Ogee Washer

Materials

Cast Iron – Traditional choice for heavy-duty or vintage-style drainage systems, though less common today.Stainless Steel – Offers excellent corrosion resistance and durability, commonly used in plumbing and marine applications. Grades like 304 and 316 are popular.

Coating

1.Hot-Dip GalvanizingA thicker zinc coating applied by dipping the washer in molten zinc, offering superior rust protection for outdoor or industrial use.

2.Passivation (for Stainless Steel)

A chemical treatment that removes free iron from stainless steel surfaces, enhancing corrosion resistance while maintaining a natural metallic appearance.

Key Features of an Ogee Washer:

1.S-Shaped Design – The curved "ogee" (double curve resembling an elongated S) allows the washer to flex slightly, accommodating minor misalignments and reducing stress concentrations.2.Load Distribution – It helps distribute the load from a bolt or nut over a wider area, preventing damage to softer materials like wood or composite structures.

3.Vibration Resistance – Often used in applications where vibrations or dynamic loads are present, helping maintain bolt tension.

Applications:

Structural Steelwork – Used in bolted connections for beams, columns, and trusses.Timber Construction – Prevents crushing of wood when tightened with bolts.

Bridge & Heavy Machinery – Provides stability in high-stress environments.

Comparison to Other Washers:

Unlike flat washers, ogee washers have a contoured shape for better flexibility.They differ from spring washers, which are designed primarily to prevent loosening, whereas ogee washers focus on load spreading and alignment.

Materials

|

Product Name |

Ogee washers |

|

Material |

carbon steel,stainless steel |

|

Size |

Diameter: ID: ½ inch (12.7 mm) to 2 inches (50.8 mm) OD: 1.5 inches (38.1 mm) to 4 inches (101.6 mm) Thickness: 1/16 inch (1.6 mm) to ¼ inch (6.4 mm) |

|

Surface |

Hot-Dip Galvanizing,Passivation |

|

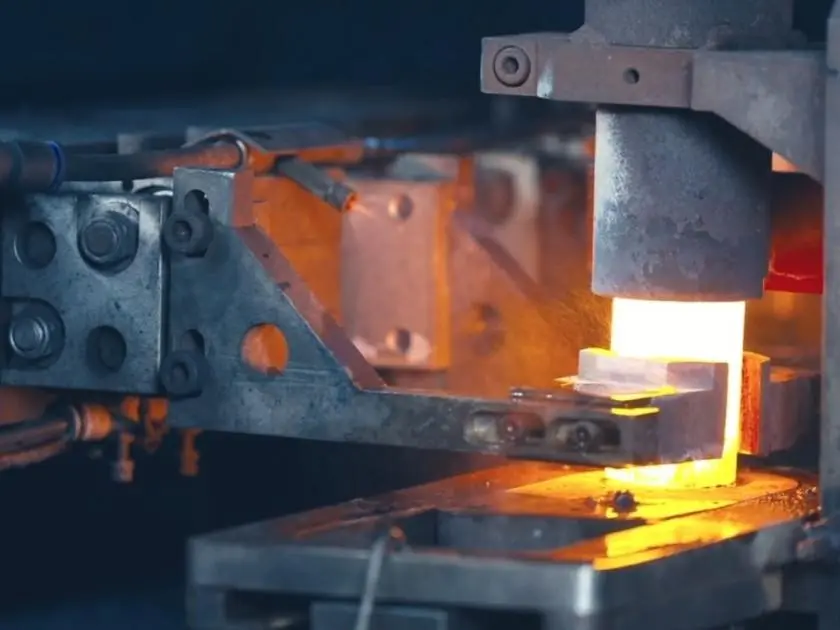

Production Process |

Casting |

|

MOQ |

800KG |

|

Package |

Carton & Pallet |

Product Services

1.After-sales quality control: After finished product inspection, ensure that it meets customer requirements.

2.Cooperation services: We can provide customers with OEM and ODM services to customize products to ensure that customer requirements are met.