Stamping parts

Description

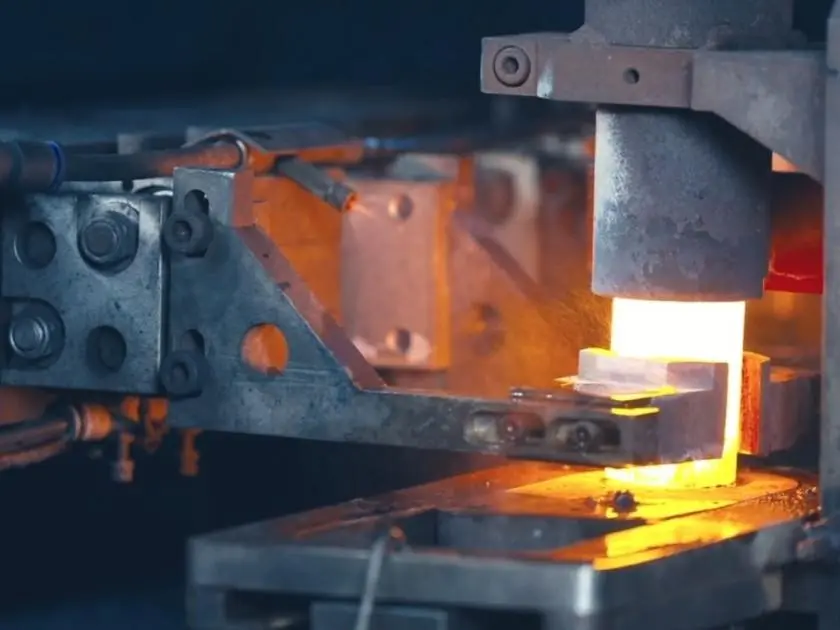

The production of stamped metal components follows a systematic sequence of operations to transform raw sheet metal into finished products. The workflow is organized as follows:

1. Blanking

The process initiates with blanking, where flat sheet metal is precisely cut into designated shapes using specialized dies. This critical first step establishes the fundamental geometry and dimensional baseline for subsequent operations.

2. Piercing

Punching operations create functional apertures or through-holes in predetermined locations. Precision tooling ensures dimensional accuracy and edge quality for mechanical fastening or assembly requirements.

3. Flanging (Bilateral)

Dual-side flanging forms raised edges along specified boundaries through controlled material deformation. This bilateral edge formation enhances structural rigidity while preparing for potential joining operations or interface connections.

4. Trimming

Peripheral trimming removes residual material from formed edges using contour-matching dies. This operation achieves final dimensional specifications and eliminates processing-induced excess material.

5. Cylindrical Forming

Roll bending or rotary die processes gradually curve the blank into cylindrical geometries. Progressive curvature control prevents material stress concentration and maintains wall thickness uniformity.

6. Pre-forming

Intermediate shaping prepares components for final geometry through partial deformation. This transitional phase minimizes spring back effects and optimizes material flow characteristics.

7. Final Forming

Definitive shaping achieves target contours through high-precision dies. Controlled pressure application ensures compliance with strict dimensional tolerances and surface finish requirements.

8. Calibration

Post-forming calibration stabilizes component geometry through micro-adjustments. Stress-relief treatments and localized corrections compensate for residual elastic deformation, ensuring long-term dimensional stability.

This optimized sequence balances material utilization efficiency with dimensional precision, incorporating progressive deformation stages to minimize defects. Each operation builds upon previous results through specifically engineered tooling systems, ensuring repeatable production of complex stamped components. The process emphasizes controlled material flow management to maintain structural integrity while achieving design specifications.

Product Information

|

Product Name |

Stamping parts |

|

NO. |

|

|

Material |

Carbon steel |

|

Size |

|

|

Weight |

|

|

Surface |

Hot dip galvanized per ASTM A-153 |

|

Production Process |

Stamping |

|

MOQ |

2000pcs |

|

Package |

Carton & Pallet |

|

Usage Scenarios |

Connecting the spool insulator on the pole |

Product Services

1.After-sales quality control: After finished product inspection, ensure that it meets customer requirements.

2.Cooperation services: We can provide customers with OEM and ODM services to customize products to ensure that customer requirements are met.

Frequently Asked Questions

tion 1: Are you a factory or a trading company?

Answer: We have 30+ experience of hardware professional manufacturer

Question 2: Where is your factory?

Answer: The factory is located in Beilun District,Ningbo City,Zhejiang Provice,China,which is very close to Ningbo Port.

Question 3: What are the payment methods?

Answer: T/T payment method;L/C

Question 4: What shipping methods do you have?

Answer: We have transportation department and freight forwarder. The specific freight plan can also be customized according to your needs

Question 5: Does your factory have standards for quality control?

Answer: Our factory is certified with ISO9001,TS16949,ISO17025. We have a professional and strict QC management to follow up for each shipment.

Question 6: What are your advantages compared to your competitors?

Answer: We have excellent advantages in R&D strength and industry experience, and the same time, product customization and diversification can fully meet your business needs.

Question 7: Who are your other customers?

Answer: We export to the countries all over the world

Question 8: Can you provide product samples?

Answer: We can provide the sample for you to test and check the quality.

estion 9: Does it support customized products?

Answer: We support customized products. We have a professional R&D team to design customized products. Give us your opinion of function, we can provide our design to you.

Sign up for our newsletter

We are Weiye Group, an innovative and dynamic company with over three decades of experience in the manufacturing sector.